Pic request: needle valve mounting

#1

Pic request: needle valve mounting

Picked up the WH6820 needle valve and needed fittings at Napa yesterday. Looking for ideas on how to mount the valve someway so that the tubing isn't supporting it. I'm leaning towards mounting it where the old filter housing used to live. The issue is, mounting the valve itself to something.

#3

Oh, nevermind. Must have deleted it...

There are some around here somewhere though, most of my FP gauge questions on 2nd gens were answered by a member named moparman1973, not sure if he is here anymore, but he had some detailed pics.

Should be just taking off the back test (schrader) port and plumbing in there with a 1/8" brass nipple.

There are some around here somewhere though, most of my FP gauge questions on 2nd gens were answered by a member named moparman1973, not sure if he is here anymore, but he had some detailed pics.

Should be just taking off the back test (schrader) port and plumbing in there with a 1/8" brass nipple.

#4

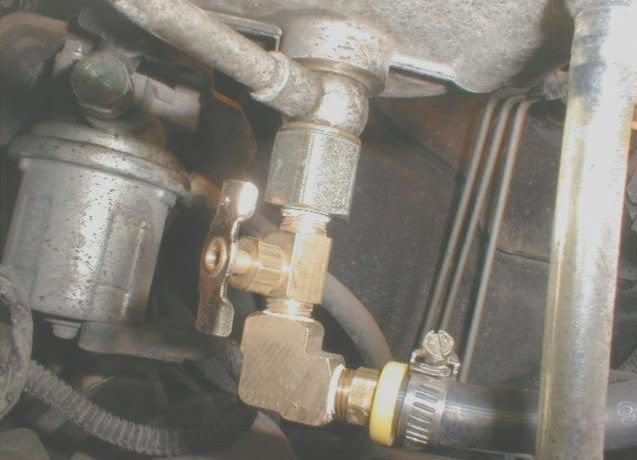

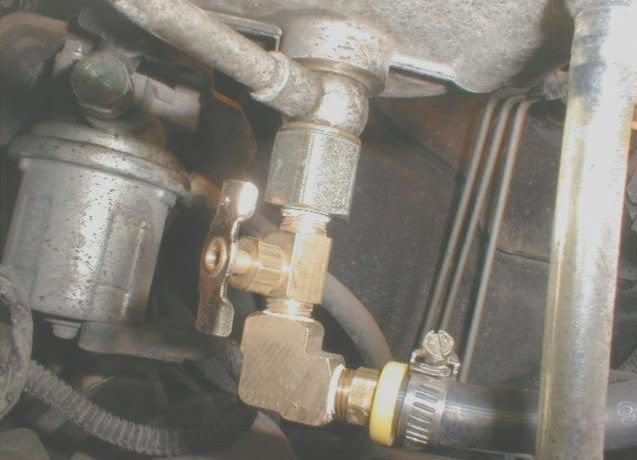

I personally think its better to take the fuel pressure off the filter canister rather than tie up the test port on the VP-44. There may be a time that you have to verify your guage operation and need to use the test port.

I think this is the best way to go (this is an 01 as well):

I think this is the best way to go (this is an 01 as well):

#5

Sorry, I guess I left out info.

I do not have the factory lift pump nor factory filter housing. I am running a full FASS setup.

I currently have a gauge taking pressure from approx 10" from the VP44. I want to mount the valve in such as way that is isn't just flopping around.

Thanks again guys.

I do not have the factory lift pump nor factory filter housing. I am running a full FASS setup.

I currently have a gauge taking pressure from approx 10" from the VP44. I want to mount the valve in such as way that is isn't just flopping around.

Thanks again guys.

#7

Still needing more info...is that 1/2" line?

This might work for you:

http://www.vulcanperformance.com/ser...-fdsh-2/Detail

This might work for you:

http://www.vulcanperformance.com/ser...-fdsh-2/Detail

Trending Topics

#9

Still needing more info...is that 1/2" line?

This might work for you:

http://www.vulcanperformance.com/ser...-fdsh-2/Detail

This might work for you:

http://www.vulcanperformance.com/ser...-fdsh-2/Detail

#11

Thread

Thread Starter

Forum

Replies

Last Post

bobwhite

Performance and Accessories 2nd gen only

20

11-18-2006 08:39 AM

BigBlueDodge

3rd Generation Ram - Non Drivetrain - All Years

22

11-06-2006 04:53 PM

turbodave

3rd Gen High Performance and Accessories (5.9L Only)

3

02-10-2006 04:29 PM