fuel pressure guage

#1

fuel pressure guage

how important is it? we r definetely interested in finding out! nothing is cheap on these trucks! we have already sunk alot of money on this truck(problem wise and cost) and any prevention would be a great help, thanks

#2

Fuel Pressure is VERY IMPORTANT! - You can damage your VP44/Injection pump if your fuel pressure falls below 5-8 PSI... VP44 cost about $1,300.00-$1,600.00!!!!

Then Pyrometer....

Then Boost...

Then Trans Temp (If automatic)

Then Pyrometer....

Then Boost...

Then Trans Temp (If automatic)

#6

Originally Posted by J BODY

No fuel psi gauge here.

I lost my first VP44 from a bad LP pump... I've installed a fuel pressure guage right after that. I'm looking down the road of buying a holley blue... Cruise pressure is right around 10 PSI and falling. So I'm doing my research now...

I lost my first VP44 from a bad LP pump... I've installed a fuel pressure guage right after that. I'm looking down the road of buying a holley blue... Cruise pressure is right around 10 PSI and falling. So I'm doing my research now...

#7

Look at JEGS.com for the Bully dog fuel managemant system i got one and now am running 22psi idle and 15psi WOT.

Pretty easy to install and comes with all new fuel line to run from the tank to the stock lift pump. I am running from the inside frame rail at the tank to and through the stock lift pump. the kit comes with all the necessary fittings.

scotte

Pretty easy to install and comes with all new fuel line to run from the tank to the stock lift pump. I am running from the inside frame rail at the tank to and through the stock lift pump. the kit comes with all the necessary fittings.

scotte

Trending Topics

#8

Originally Posted by scottsjeeprolet

Look at JEGS.com for the Bully dog fuel managemant system i got one and now am running 22psi idle and 15psi WOT.

Pretty easy to install and comes with all new fuel line to run from the tank to the stock lift pump. I am running from the inside frame rail at the tank to and through the stock lift pump. the kit comes with all the necessary fittings.

scotte

Pretty easy to install and comes with all new fuel line to run from the tank to the stock lift pump. I am running from the inside frame rail at the tank to and through the stock lift pump. the kit comes with all the necessary fittings.

scotte

http://www.jegs.com/webapp/wcs/store...tegoryId=25301

Q: Is that a holley blue pump on there? Can't tell...

#10

Originally Posted by TxDiesel007

Any instructions as to how to install them on a 12V?

Tx

Tx

I drill and tap the top of the injection pump banjo bolt to 1/8'' pipe

thread, then install a male x female 1/8'' needle valve with 1/8'' tubing

compression fitting in it. Boost gauge or oil pressure tubing pushed

though some 1/4'' tubing to protect against cuts and kinks to the gauge.

For a gauge you can use a fuel, boost or water pressure gauge, for a 12

valve it must be at least 40 psi, 60 is ideal. I use rear connected, liquid filled,

stainless water pressure gauges and make my own mount. They have no

lighting but it's not a gauge you need to look at all the time. They can

be mounted low for the same reason. Use no Teflon tape, it doesn't work

with diesel. Instead use anti-seize or Permatex #2. Remember you are

working on the clean side of the filter, keep everything spotless.

Compression fittings with a ferrule that slips over the tubing will leak

if overtightened, finger tight with one half turn of a wrench is plenty.

The ferrule should be replaced if the fitting is ever removed.

If you can tap your manifold for a pyro tapping the banjo bolt is a piece

of cake. Just drill from the inside to keep the hole straight and tap from

the outside. You can also connect to the bleed screw on top of your fuel

filter with the appropriate adapter to tubing if you don't want to tap.

The adaptor is available from TST for $25 they say it is only for temporary use though http://www.tstproducts.com/service_tools_trial.htm . After the install start your

engine with the needle valve closed then open it slowly till someone in

the cab signals you that it's just reading pressure. If you tighten down

the packing nut under the valve handle the setting can't move. The valve

will control pulsation and buzzing and can also be shut down in the

unlikely event that you have a leak. Without a valve to restrict the flow

the gauge will pulsate so badly that you won't be able to read it in the

short time before it self destructs.

Parts list; 1/8'' needle valve - $2.50 from the hardware store, plastic

oil pressure tubing kit that comes with the compression fittings - under $10

from any auto parts store. 1/4'' tubing for protective sleeve - less than $2.

Gauge is your choice and may come with tubing. The water pressure gauges I

use cost less than $10, bringing the total cost to less than $20 and a

couple hours of your time.

From Grainger, needle valve http://www.grainger.com/Grainger/pro...835462&ccitem=

#11

Yes it is a Holley Blue pump.

The installation is pretty straight foreward.

I used a relay to operate the pump. just tapped into the stock LP for the relay trigger.

Merry christmas

scotte

The installation is pretty straight foreward.

I used a relay to operate the pump. just tapped into the stock LP for the relay trigger.

Merry christmas

scotte

#12

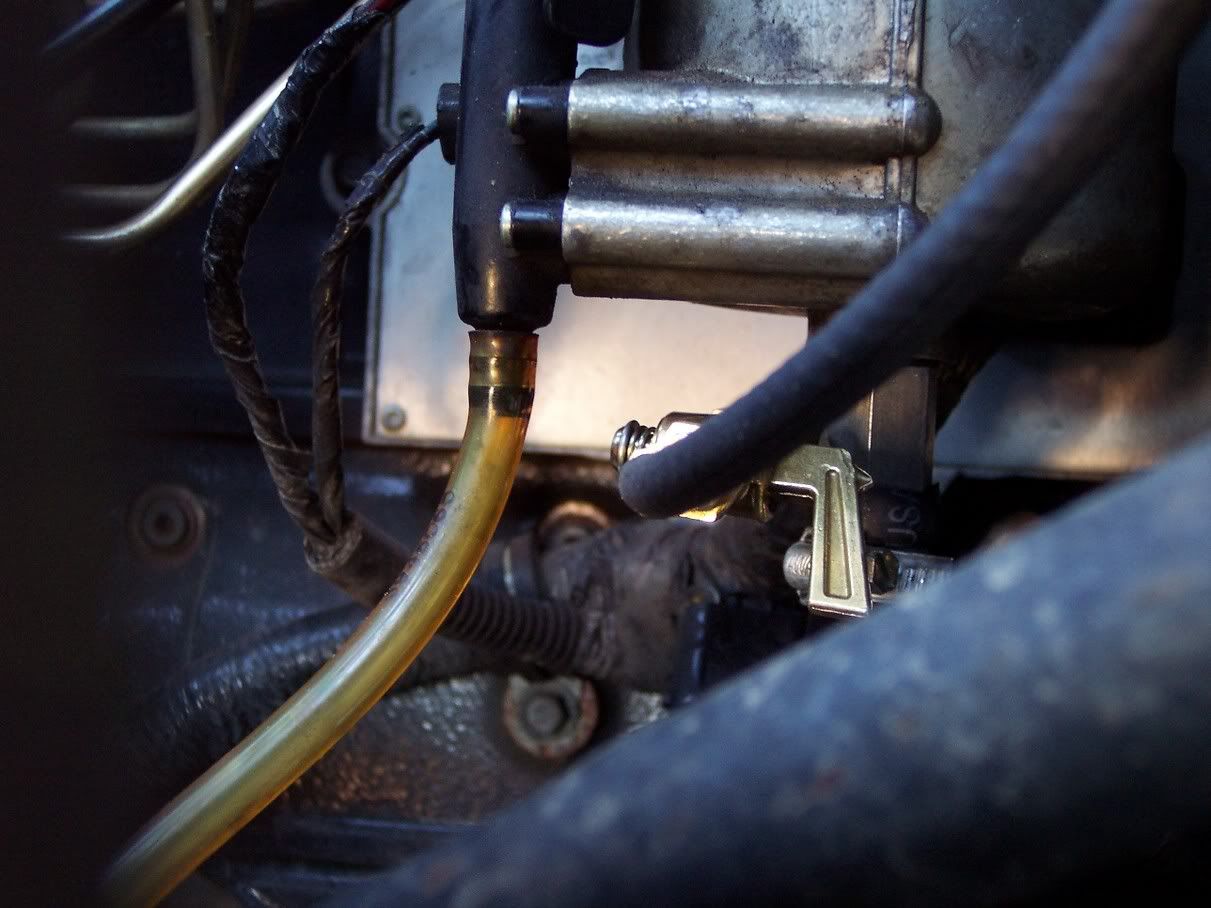

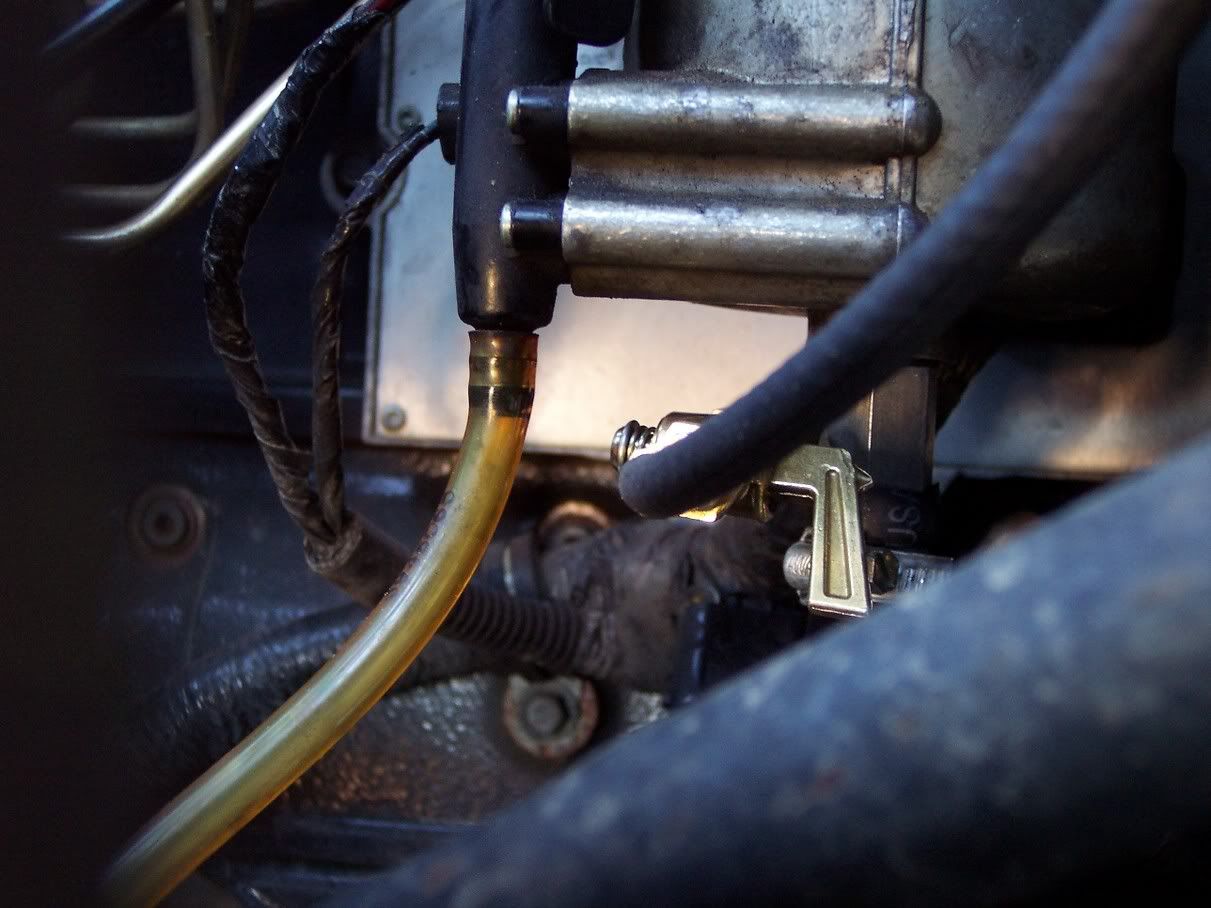

Heres a really bad picture from a bad anlge of my newly installed set up.

I used a 1/8" NPT ball valve (under $5 USD) from Nappy. I decided to use a street 90* to make the line come out perpendicular to the filter canister. This way I have a more natural anlge back to the firewall and up to the gauge. The rubber hose you see is also from NAPA, I used it to "sheath" the poly tubing supplied with the gauge. This way I don't have to worry about something rubbing it or getting pinched and what not. Thank's to Infidel for making me not being afraid of using "boost" tubing with the FP gauge as long as it's protected by another hose. Trust me, the ball valve allows Very little actual flow to the gauge, I tested it a few ways with air proir to deciding to install it. The sweep is nice an smooth. I'm pretty confident of the install, it went smooth. I went with the Vulcan big line (and LP relocation) kit, the fitting he includes for the outlet to the VP from the filter has a 1/8" NPT hole for the FP tap.

No Banjos here anymore.

I also lost a VP due to a $100.00 pump failing and me not knowing it. Anyone out of warranty and riding around oblivious to their Fuel Pressure is playing with fire.

I used a 1/8" NPT ball valve (under $5 USD) from Nappy. I decided to use a street 90* to make the line come out perpendicular to the filter canister. This way I have a more natural anlge back to the firewall and up to the gauge. The rubber hose you see is also from NAPA, I used it to "sheath" the poly tubing supplied with the gauge. This way I don't have to worry about something rubbing it or getting pinched and what not. Thank's to Infidel for making me not being afraid of using "boost" tubing with the FP gauge as long as it's protected by another hose. Trust me, the ball valve allows Very little actual flow to the gauge, I tested it a few ways with air proir to deciding to install it. The sweep is nice an smooth. I'm pretty confident of the install, it went smooth. I went with the Vulcan big line (and LP relocation) kit, the fitting he includes for the outlet to the VP from the filter has a 1/8" NPT hole for the FP tap.

No Banjos here anymore.

I also lost a VP due to a $100.00 pump failing and me not knowing it. Anyone out of warranty and riding around oblivious to their Fuel Pressure is playing with fire.

#15

Originally Posted by Dr. Evil

P.J. - Im curious why you would choose a ball valve rather instead of a needle valve??

You would get much better pressure regulation with a needle valve.

You would get much better pressure regulation with a needle valve.

I am pretty confident with the ball valve, I know it's probably much more flow (when just cracked) than a needle, but the dampening should be the same. I looked at this valve for a week thinking if I should have went needle like everyone else. When just barely (barely) cracked I could hardly squeek a hiss (for lack of a better explination) of air passed it while holding 90psi of blow gun on it.

Conventional way, no. Going to work out? We'll see.