H2O Pressure

#77

Registered User

Thread Starter

Wetspirit - Let me clarify:

Thermal energy transfer by conduction begins to take place upon physical contact, but the heat transer is a process - not an event. The more time two materials are touching, the closer they will come to achieving thermal equilibrium. The coolant in the water jacket doesn't remain there long enough to absorb all of the waste energy from the combustion process...

Tangentially, the extra (that's an understatement! ) waste heat generated by the fuel/air mixture does not immediately transfer all of it's thermal energy through the cylinder wall into the coolant medium.

) waste heat generated by the fuel/air mixture does not immediately transfer all of it's thermal energy through the cylinder wall into the coolant medium.

I believe that the large heat load placed upon the coolant system by heavy fueling does raise system pressure, but I doubt that it is the sole (or major) reason for the freeze plugs blowing out. I wouldn't be surprised if the extra heat load is insignificant to the issue - seems as though there'd be many more incidences of blow-out from hot CTDs... they can get mighty hot towing heavy up the hills, and that happens far more than racing them!

I'm surprised that more people aren't seeing the common thread that is unique to these blow-outs.

Thermal energy transfer by conduction begins to take place upon physical contact, but the heat transer is a process - not an event. The more time two materials are touching, the closer they will come to achieving thermal equilibrium. The coolant in the water jacket doesn't remain there long enough to absorb all of the waste energy from the combustion process...

Tangentially, the extra (that's an understatement!

) waste heat generated by the fuel/air mixture does not immediately transfer all of it's thermal energy through the cylinder wall into the coolant medium.

) waste heat generated by the fuel/air mixture does not immediately transfer all of it's thermal energy through the cylinder wall into the coolant medium.I believe that the large heat load placed upon the coolant system by heavy fueling does raise system pressure, but I doubt that it is the sole (or major) reason for the freeze plugs blowing out. I wouldn't be surprised if the extra heat load is insignificant to the issue - seems as though there'd be many more incidences of blow-out from hot CTDs... they can get mighty hot towing heavy up the hills, and that happens far more than racing them!

I'm surprised that more people aren't seeing the common thread that is unique to these blow-outs.

#78

all the guy's blowing plugs are heavily modified truck's with.....

big turbos and programmers that fuel way past redline...

with the post's you made it sounds like you know why they are blowing????

what do you think????

#79

Registered User

Join Date: Mar 2004

Location: Fair Oaks CA

Posts: 847

Likes: 0

Received 0 Likes

on

0 Posts

the Dodge ISB has a max. block coolant press. of 57 psi with 50/50 coolant mix , thermostat open and radiator cap off. you will see higher pressure in the block area and less pressure in the cyl. head area , the head gasket coolant hole's are orifice for the coolant flow, if not , the coolant flow would be to fast to obsorb the heat from the cylinders. I know Cummins has had issue's with customers replacing some block freeze plugs with parts house freeze plugs and blowing them out on other engines, guys that are having issues should hook up a pressure gage to the block area just behind the oil cooler cavity and see what kind of pressure they are running.

#80

Registered User

Thread Starter

John, is 57 psi the max output of the water pump at the ISB's rated power RPM? I'm assuming at essentially zero S.P. since t'stat is open and radiator cap off...

Any chance of getting a pump head/pressure curve for one of those?

Any chance of getting a pump head/pressure curve for one of those?

#82

#83

DTR's 'Wrench thrower...' And he aims for the gusto...

Join Date: Oct 2003

Location: Smith Valley, NV (sometimes Redwood City, CA)

Posts: 2,668

Likes: 0

Received 3 Likes

on

2 Posts

[QUOTE=XLR8R;1482947]Wetspirit - Let me clarify:

Thermal energy transfer by conduction begins to take place upon physical contact, but the heat transer is a process - not an event. The more time two materials are touching, the closer they will come to achieving thermal equilibrium. The coolant in the water jacket doesn't remain there long enough to absorb all of the waste energy from the combustion process...

XLR8R,

You are almost seeing my point. Stay with me here for a moment. You are right that the heat transfer begins upon contact and continues till equalibrium. Thats what over heating is, if there is no water movement. We don't want qualibrium, we want as little heating of the water as possible (heating meaning temp rise, not BTUs). Not equalibrium (obviously), and not absorbing all the waste heat with a set amount of water. It's a dynamic process. No flow and the water heats to boiling and over heating. A little flow and the water heats up a lot and the cylinders cool some (normal operating temp at idle). A lot of flow and the coolant water heats a little and a lot of energy is removed from the cylinders. The basic principal behind heat transfer is to maximize the temperature differential and maximize the turbulance at the surface. Remember, we are not trying to raise the temp of the coolant. We are trying to lower or control the temp of the block. Transfer BTUs away from the block. There can only be a transfer of energy when there is a difference in temperature and the more difference the bigger the transfer. We don't wait for that difference and then intruduce more water, we move the coolant through at varying rates to match the waste heat of the engine. When the engine is putting out big HP numbers we need to move big flows to keep up. At normal conditions we need to get the engine up to temp, so the tstat restricts the flow to reduce the cooling system effectiveness to raise the engine temp. Not what we want a max heat production during racing. Get the heat (BTUs) out!

Just look at it in simpler terms. Engine cold at startup, tstat closed. Engine idling after warmup, tstat slightly open. Truck cruising down the road at 60 MPH, tstat maybe 1/2 open. 60 MPH Up a big grade while pulling on a hot day, tstat wide open (max coolant flow). Drag racing with 500 HP, at start of race idling and tstat partially open, then hammered and making the run. Now it gets interesting because of the tstat delay. Coolant water barely moving in the block but a tremendous amount of energy coming in from the cylinder walls. Over heating!!!, pressure rise because of boiling point, pop goes the plug. It's a simple and logical sequence. I'm not saying the plugs should be popping but I'm saying the conditions are right for whatever weak link there is to fail.

Thermal energy transfer by conduction begins to take place upon physical contact, but the heat transer is a process - not an event. The more time two materials are touching, the closer they will come to achieving thermal equilibrium. The coolant in the water jacket doesn't remain there long enough to absorb all of the waste energy from the combustion process...

XLR8R,

You are almost seeing my point. Stay with me here for a moment. You are right that the heat transfer begins upon contact and continues till equalibrium. Thats what over heating is, if there is no water movement. We don't want qualibrium, we want as little heating of the water as possible (heating meaning temp rise, not BTUs). Not equalibrium (obviously), and not absorbing all the waste heat with a set amount of water. It's a dynamic process. No flow and the water heats to boiling and over heating. A little flow and the water heats up a lot and the cylinders cool some (normal operating temp at idle). A lot of flow and the coolant water heats a little and a lot of energy is removed from the cylinders. The basic principal behind heat transfer is to maximize the temperature differential and maximize the turbulance at the surface. Remember, we are not trying to raise the temp of the coolant. We are trying to lower or control the temp of the block. Transfer BTUs away from the block. There can only be a transfer of energy when there is a difference in temperature and the more difference the bigger the transfer. We don't wait for that difference and then intruduce more water, we move the coolant through at varying rates to match the waste heat of the engine. When the engine is putting out big HP numbers we need to move big flows to keep up. At normal conditions we need to get the engine up to temp, so the tstat restricts the flow to reduce the cooling system effectiveness to raise the engine temp. Not what we want a max heat production during racing. Get the heat (BTUs) out!

Just look at it in simpler terms. Engine cold at startup, tstat closed. Engine idling after warmup, tstat slightly open. Truck cruising down the road at 60 MPH, tstat maybe 1/2 open. 60 MPH Up a big grade while pulling on a hot day, tstat wide open (max coolant flow). Drag racing with 500 HP, at start of race idling and tstat partially open, then hammered and making the run. Now it gets interesting because of the tstat delay. Coolant water barely moving in the block but a tremendous amount of energy coming in from the cylinder walls. Over heating!!!, pressure rise because of boiling point, pop goes the plug. It's a simple and logical sequence. I'm not saying the plugs should be popping but I'm saying the conditions are right for whatever weak link there is to fail.

#86

Registered User

Thread Starter

I think I saw your point several posts ago - which was that heavy fueling transfers enough thermal energy to the coolant to raise it's pressure enough to blow the freeze plug... did I glean that correctly from your long and thoughtful posts?

If so - no sale; it's not supported by the laws of thermodynamics, nor by empirical evidence... although as I've previously posted, I believe the excess heat load doesn't help the issue!

I really don't think you can discount the role that boost pressure plays in the problem.

Even though the thermostat's hysterisis could potentially exacerbate the problem, I should think the inherent thermal hysterisis of the cylinder wall/water jacket would cancel it out... I mean, just look at the K value for steel, or cast iron.

Factory loose-tolerance freeze plug issue aside, the trucks that have blown one share these conditions in common:

high rpm (thus higher pump outlet pressure)

high boost (probable slight lifting of the head, raising system pressure)

high heat load (raising system pressure, but not immediately)

If so - no sale; it's not supported by the laws of thermodynamics, nor by empirical evidence... although as I've previously posted, I believe the excess heat load doesn't help the issue!

I really don't think you can discount the role that boost pressure plays in the problem.

Even though the thermostat's hysterisis could potentially exacerbate the problem, I should think the inherent thermal hysterisis of the cylinder wall/water jacket would cancel it out... I mean, just look at the K value for steel, or cast iron.

Factory loose-tolerance freeze plug issue aside, the trucks that have blown one share these conditions in common:

high rpm (thus higher pump outlet pressure)

high boost (probable slight lifting of the head, raising system pressure)

high heat load (raising system pressure, but not immediately)

#87

DTR's 'Wrench thrower...' And he aims for the gusto...

Join Date: Oct 2003

Location: Smith Valley, NV (sometimes Redwood City, CA)

Posts: 2,668

Likes: 0

Received 3 Likes

on

2 Posts

[QUOTE=XLR8R;1482947]Wetspirit - Let me clarify:

Thermal energy transfer by conduction begins to take place upon physical contact, but the heat transer is a process - not an event. The more time two materials are touching, the closer they will come to achieving thermal equilibrium. The coolant in the water jacket doesn't remain there long enough to absorb all of the waste energy from the combustion process...

Tangentially, the extra (that's an understatement! ) waste heat generated by the fuel/air mixture does not immediately transfer all of it's thermal energy through the cylinder wall into the coolant medium.

) waste heat generated by the fuel/air mixture does not immediately transfer all of it's thermal energy through the cylinder wall into the coolant medium.

I believe that the large heat load placed upon the coolant system by heavy fueling does raise system pressure, but I doubt that it is the sole (or major) reason for the freeze plugs blowing out. I wouldn't be surprised if the extra heat load is insignificant to the issue - seems as though there'd be many more incidences of blow-out from hot CTDs... they can get mighty hot towing heavy up the hills, and that happens far more than racing them!

X,

One more point about that. On a long heavy tow in hot weather the increase in system temperature is controlled by the gradual opening of the tstat. No increase of pressure will happen until two conditions are met. One is that the radiator and cooling system are shedding all the heat possible. Meaning the tstat is open, the fan is running hard, etc. And the other thing is that the 3/8 inch overflow tube is flowing as hard as it can. Then the pressure in the system can begin to rise above normal. When racing, the tstat may be almost closed for the entire run so almost no cooling occurs. That leaves the vent tube. It is small and overwhelmed with that much energy. The pressure could rise to 60 PSI, for example, as the engine temp climbs past the normal boiling point of the coolant. Meanwhile the radiator is just along for the ride and stays cool with the tstat closed. Pop goes the plug.

This is simply an energy in vs energy out problem. If you can show how the pump adds to system pressure only during racing, or how boost affects cooling system pressure other than simply by making more heat, I'd like to hear it. But you are just not looking at basic heat exchanger principles and laws of heat transfer. The transfer rate through the iron has nothing to do with it because it's the water that is getting hot and the water that is moving the heat away. We are only talking about the conditions after the conduction through the iron. My final point is that this is not the "selling" of an idea. It's just a logical sequence of events based on automotive design and heat exchange principles. You have to get the heat out and how do you do it. If you don't, what happens. That simple.

Wetspirit

Thermal energy transfer by conduction begins to take place upon physical contact, but the heat transer is a process - not an event. The more time two materials are touching, the closer they will come to achieving thermal equilibrium. The coolant in the water jacket doesn't remain there long enough to absorb all of the waste energy from the combustion process...

Tangentially, the extra (that's an understatement!

) waste heat generated by the fuel/air mixture does not immediately transfer all of it's thermal energy through the cylinder wall into the coolant medium.

) waste heat generated by the fuel/air mixture does not immediately transfer all of it's thermal energy through the cylinder wall into the coolant medium.I believe that the large heat load placed upon the coolant system by heavy fueling does raise system pressure, but I doubt that it is the sole (or major) reason for the freeze plugs blowing out. I wouldn't be surprised if the extra heat load is insignificant to the issue - seems as though there'd be many more incidences of blow-out from hot CTDs... they can get mighty hot towing heavy up the hills, and that happens far more than racing them!

X,

One more point about that. On a long heavy tow in hot weather the increase in system temperature is controlled by the gradual opening of the tstat. No increase of pressure will happen until two conditions are met. One is that the radiator and cooling system are shedding all the heat possible. Meaning the tstat is open, the fan is running hard, etc. And the other thing is that the 3/8 inch overflow tube is flowing as hard as it can. Then the pressure in the system can begin to rise above normal. When racing, the tstat may be almost closed for the entire run so almost no cooling occurs. That leaves the vent tube. It is small and overwhelmed with that much energy. The pressure could rise to 60 PSI, for example, as the engine temp climbs past the normal boiling point of the coolant. Meanwhile the radiator is just along for the ride and stays cool with the tstat closed. Pop goes the plug.

This is simply an energy in vs energy out problem. If you can show how the pump adds to system pressure only during racing, or how boost affects cooling system pressure other than simply by making more heat, I'd like to hear it. But you are just not looking at basic heat exchanger principles and laws of heat transfer. The transfer rate through the iron has nothing to do with it because it's the water that is getting hot and the water that is moving the heat away. We are only talking about the conditions after the conduction through the iron. My final point is that this is not the "selling" of an idea. It's just a logical sequence of events based on automotive design and heat exchange principles. You have to get the heat out and how do you do it. If you don't, what happens. That simple.

Wetspirit

#88

Banned

Quote: 2 - The engine is started - the pump rotates and generates a differently between the pump inlet (radiator) and pump outlet (block). The flow does not return to the radiator as the thermostat is closed. The pressure in the block raises due to high head no flow condition. The pressure in the radiator drops initially due to the pumps suction of fluid from the radiator.

Camper,

The pump suction side is the block. Water moves from the block through the pump to the radiator. The pump does not pressurize the block. The big pressure buildup is from the big heat build up.

Wetspirit

Camper,

The pump suction side is the block. Water moves from the block through the pump to the radiator. The pump does not pressurize the block. The big pressure buildup is from the big heat build up.

Wetspirit

Sorry Wetspirit your a little wet on this one flow is cold from the rad to the block the outlet is at the thermostat.

I would hazard to say 100% of ALL internal combustion piston engines are run with pressurized coolant in the blocks to help minimize the coolant from flashing. Higher pressure is a higher boiling point.

#89

Banned

If you want worse case dead head pressure use one of the head ports near the back of the head by #6.

#90

Registered User

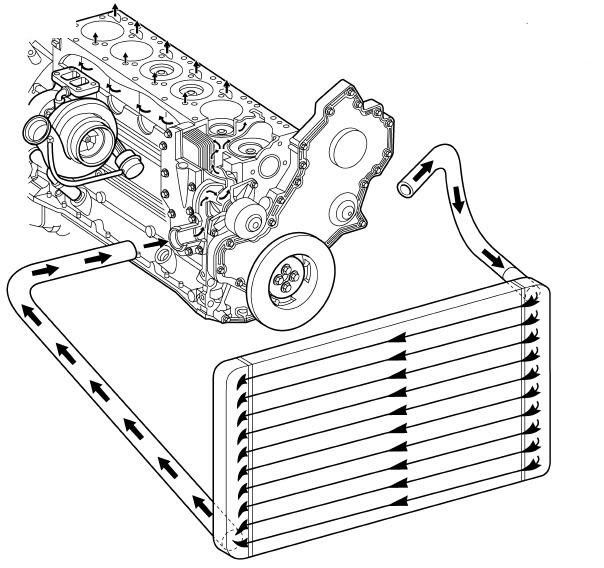

Thanks for the diagram. Where did you find that?

Also, do you think tee-ing off of the feed line before the t-stat and somehow running another coolant line to the back of the head at or before number six cylinder might aid in cooling? I seem to remember something like this being done on high performance small blocks to help cool off the hotter running rear cylinders.

Also, do you think tee-ing off of the feed line before the t-stat and somehow running another coolant line to the back of the head at or before number six cylinder might aid in cooling? I seem to remember something like this being done on high performance small blocks to help cool off the hotter running rear cylinders.