^^^PROBLEM SOLVED^^^ No more 1/4, 1/8, low fuel Cavitation issues^^^

#1

^^^PROBLEM SOLVED^^^ No more 1/4, 1/8, low fuel Cavitation issues^^^

----------ALL LOW FUEL ISSUES HAVE BEEN RESOLVED!------

One of the main reasons these trucks are having low fuel level cavitation issues is because of the large lift pumps that are being installed. With the volume of fuel that these lift pump are moving it causes the fuel to swirl around the pickup tube (draw straw) and is even more apparent at low fuel levels!!!!! -----EXAMPLE-----When you flush a toilet the water swirls around the bowl therefore causing a low center point in the middle----- the pickup tube is causing the same issue, which in turn causes cavitation and air in the lines.

The idea here is placing a funnel upside down about 1/16 of and inch off of the bottom of the tank. By doing so you are allowing the pickup tube to draw across a 2 inch area instead of the original .5 inch size. It takes A LOT more to make the fuel swirl around the 2 inch pickup than .5 inch. In testing we were NOT able to get even 10% of the swirling effect around the larger size pickup. With the .5 inch tube it was swirling and cavitating within 30 seconds of pump start up.

I have been running this setup for a few months without ANY issues and I have had the fuel light on multiple times for 18,19,21 miles before filling the tank.

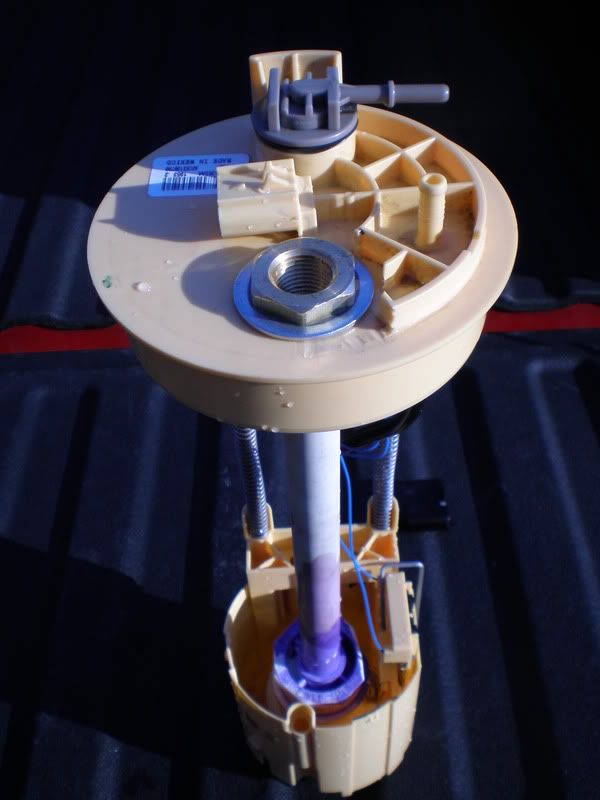

Here is the install of the fuel pickup tube-----

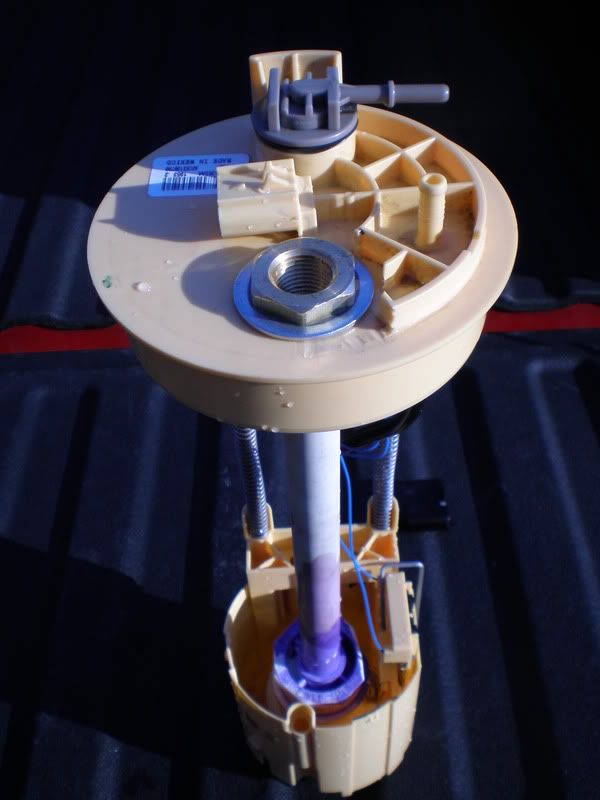

I purchased a new bulkhead fitting that was smaller so the I could plumb it into the top of the stock canister. Also I purchased and extra washer and O-ring to seal it.

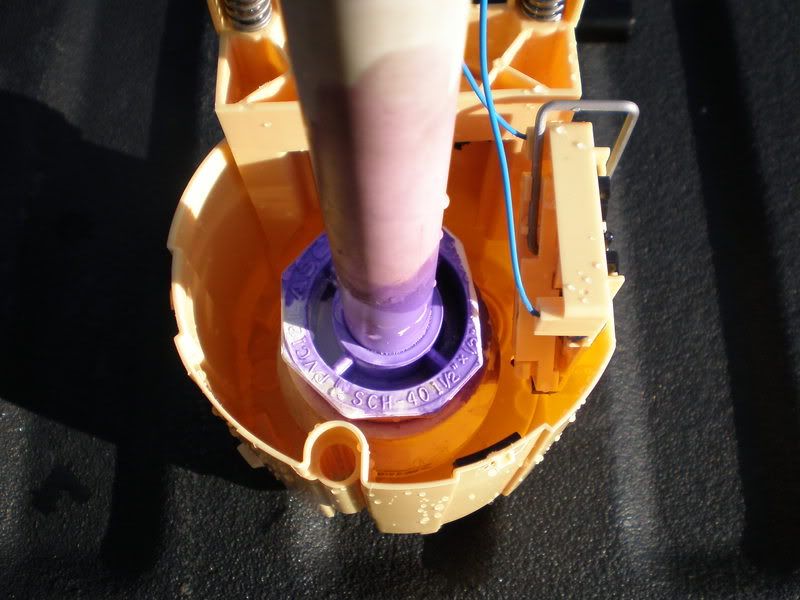

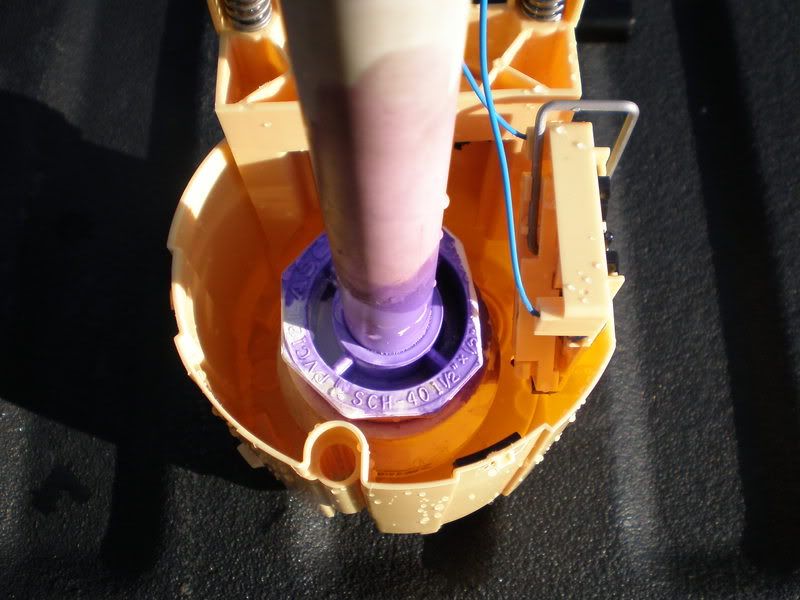

I purchased PVC .5 inch to 1.5 reducer and 1.5 inch to 2 inch reducer and glued them together.

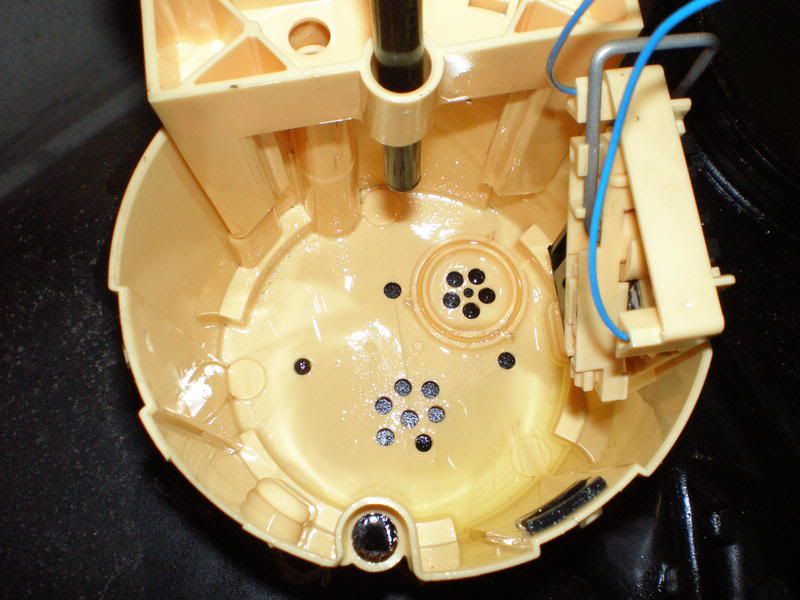

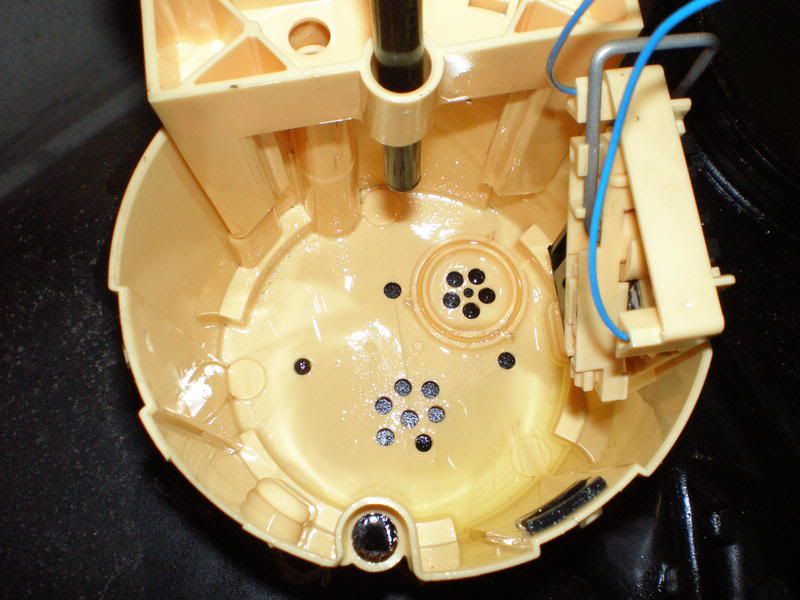

This view shows the upside down "funnel" that was placed 1/16 inch off the bottom of the canister

Here is the new bulkhead fitting, .5 inch draw tube, .5 inch reducer and 2 inch reducer all glued and ready to install (I went a little crazy with the purple primer)

Removed the in canister lift pump, flapper on the bottom and drilled 7 more holes directly under where the new upside down funnel will be placed to get more fuel up into the canister.

Use a dremel tool to remove some of the "waffle" structure on the canister lid to make room for the new bulkhead fitting.**proper placement of the bulkhead fitting is EXTREMELY important.** The new "funnel" is within 1/16 inch off of the bottom once installed back in the tank.

Remove some material on the right side of the pickup to make clearance for the fuel gauge float. It is a very snug fit in the canister and proper placement of the bulkhead fitting is EXTREMELY important.

Reinstall canister and double check all connections!!!! I have NOT seen less than 5 PSI lift pressure since this project was completed.

One of the main reasons these trucks are having low fuel level cavitation issues is because of the large lift pumps that are being installed. With the volume of fuel that these lift pump are moving it causes the fuel to swirl around the pickup tube (draw straw) and is even more apparent at low fuel levels!!!!! -----EXAMPLE-----When you flush a toilet the water swirls around the bowl therefore causing a low center point in the middle----- the pickup tube is causing the same issue, which in turn causes cavitation and air in the lines.

The idea here is placing a funnel upside down about 1/16 of and inch off of the bottom of the tank. By doing so you are allowing the pickup tube to draw across a 2 inch area instead of the original .5 inch size. It takes A LOT more to make the fuel swirl around the 2 inch pickup than .5 inch. In testing we were NOT able to get even 10% of the swirling effect around the larger size pickup. With the .5 inch tube it was swirling and cavitating within 30 seconds of pump start up.

I have been running this setup for a few months without ANY issues and I have had the fuel light on multiple times for 18,19,21 miles before filling the tank.

Here is the install of the fuel pickup tube-----

I purchased a new bulkhead fitting that was smaller so the I could plumb it into the top of the stock canister. Also I purchased and extra washer and O-ring to seal it.

I purchased PVC .5 inch to 1.5 reducer and 1.5 inch to 2 inch reducer and glued them together.

This view shows the upside down "funnel" that was placed 1/16 inch off the bottom of the canister

Here is the new bulkhead fitting, .5 inch draw tube, .5 inch reducer and 2 inch reducer all glued and ready to install (I went a little crazy with the purple primer)

Removed the in canister lift pump, flapper on the bottom and drilled 7 more holes directly under where the new upside down funnel will be placed to get more fuel up into the canister.

Use a dremel tool to remove some of the "waffle" structure on the canister lid to make room for the new bulkhead fitting.**proper placement of the bulkhead fitting is EXTREMELY important.** The new "funnel" is within 1/16 inch off of the bottom once installed back in the tank.

Remove some material on the right side of the pickup to make clearance for the fuel gauge float. It is a very snug fit in the canister and proper placement of the bulkhead fitting is EXTREMELY important.

Reinstall canister and double check all connections!!!! I have NOT seen less than 5 PSI lift pressure since this project was completed.

#5

CRAZY!!

what fuel pump are you using??? GPH??

once I moved the drawstraw to the canister I did not have 1/4 tank fluctuating pressure..I thought most the 1/4 problems were from fuel sloshing back and forth in the tank???..leaving the drawstraw without any fuel too pick-up..

nice job it's good to see some more people trying to resolve this.

what fuel pump are you using??? GPH??

once I moved the drawstraw to the canister I did not have 1/4 tank fluctuating pressure..I thought most the 1/4 problems were from fuel sloshing back and forth in the tank???..leaving the drawstraw without any fuel too pick-up..

nice job it's good to see some more people trying to resolve this.

#6

Once bonded and cured the PVC and PVC glue is not effected by diesel!!!!

Mark,

This is on my personal truck and I am running the AD 150. After seeing all of the issues guys have been struggling with I knew that there had to be a better way. Digging into it more this is what I came up with.

Sloshing fuel is also a large part of the problem when the pickup is NOT drawing from the canister!!!!!!!!

Mark,

This is on my personal truck and I am running the AD 150. After seeing all of the issues guys have been struggling with I knew that there had to be a better way. Digging into it more this is what I came up with.

Sloshing fuel is also a large part of the problem when the pickup is NOT drawing from the canister!!!!!!!!

#7

So this is a AD150 kit your using? Did you have the 1/4 issues before this mod? On the top of your canister I see you have a black rubber hose going somewhere, what is that? Also you have a metal and grey plastic bulkhead fittings, whats the plastic one for? The actual draw straw tube, is that pvc to? Are you using the factory return?

Trending Topics

#8

So this is a AD150 kit your using? Did you have the 1/4 issues before this mod? On the top of your canister I see you have a black rubber hose going somewhere, what is that? Also you have a metal and grey plastic bulkhead fittings, whats the plastic one for? The actual draw straw tube, is that pvc to? Are you using the factory return?

Yes, I changed all of this before installing the AD. I did not want to have any issues or to do the job twice so I played with revamping the pickup tube stuff for about a month before installing it. The black hose on the canister is the return line from the CP3. Because the bulkhead fitting was mounted in the top of the canister, I had to cut off the stock feed and return fittings.

Plastic bulkhead fitting came with the AD kit.

The draw tube that came with the kit is PVC which is why I chose to make the "upside down funnel" out of PVC as well.

I re-routed the factory CP3 return line where you see the black hose on top of the canister. I also forgot to mention that I put a fitting in the bottom of the black hose inside the canister to lengthen it almost to the bottom. By doing so, in a low fuel situation it will NOT splash the return fuel in the bottom of the canister and add air/foam.

#9

Awesome! Im thinking of giving this a shot! Where did you get the metal bulkhead fitting from? So you said that drawstraw you used is actually pvc and came with the ad kit??? You just lengthen the return line in the canister? Whats that grey hookup on top of canister still there?

#10

See the only thing I have a concern with is, how far down in the reducer does the drawstraw go?? Of course that big ole 2 inch diameter is good but if the bottom of that is only 1/16 from the bottom of the canister but how far is the actual drawstraw from the bottom.. Does the pump have enough suction power to actually suck the actual fuel up through the air, if say fuel is only a quarter of the way up that reducer and your draw straw stops way up top of that reducer???? See what Im saying?? There will be nothin but air for a half inch or more between the fuel and actual bottom of the draw straw if your tank is low..

#12

Registered User

Joined: Jan 2007

Posts: 1,820

Likes: 1

From: My head lays down in Murrieta, but the day light hours are spent in San Diego, Ca.

So you removed the intank lift pump from the canister. Was that difficult? Or should my question really be , is there a lot of modification to remove the pump? I'm thinking this is my project for this weekend on my 2000.

#13

Registered User

Joined: Jan 2007

Posts: 1,820

Likes: 1

From: My head lays down in Murrieta, but the day light hours are spent in San Diego, Ca.

#14

So is the white drawstraw your AD Return line and the clear ether hose is your AD feed line? Couldn't you just use like (2) 1/2" draw straws flexible ones from like gdp and use them both for AD return and feed and then still use your factory return line? Is there any specific reason why you used that clear ether like you did and not a drawstraw? Also I wanted to ask how did you put a load on the springs and compensate for how much hose to cut off so it was right lenght so when you put it back in the tank? Do you think running 2 drawstraws would be better? Also how come you did your factory return like that? Was the stock one no good? Also do you have to use the factory return line or is the AD return enough fuel return? Are these gdp drawstraws the best ones to use?

http://www.glacierdieselpower.com/pr...spx?pf_id=DS-2

I ask because this is what my canister looks like up top minus the fuel fitting they already plumbed in(not my actual Canister). That grey fitting on the left side, is a vent right? If I put some type of other vent on the tank. I ask because if i put another vent and take that grey piece out I could put the AD feed like this picture and take that grey fitting out and put a AD return there and use the black hose just like this guy did as the factory return line into the canister and be good to go!! What ya think?? Follow me?

http://www.glacierdieselpower.com/pr...spx?pf_id=DS-2

I ask because this is what my canister looks like up top minus the fuel fitting they already plumbed in(not my actual Canister). That grey fitting on the left side, is a vent right? If I put some type of other vent on the tank. I ask because if i put another vent and take that grey piece out I could put the AD feed like this picture and take that grey fitting out and put a AD return there and use the black hose just like this guy did as the factory return line into the canister and be good to go!! What ya think?? Follow me?

I got the bulkhead fitting at a local hose shop anyone should have one, Fleet Farm, Farm and Fleet, TSC, etc. It is 1/2" I.D.

Yes the grey fitting is a tank vent and should NOT be removed. Another thing I didn't mention is that I had previously installed the Tank Vent Mod, so I used the factory vent for the AD return. Too bad the AD kit doesn't come with the Tank Vent Mod and suggest it be installed at the same time as the AD. That would allow for the factory tank vent to be used for the AD return and give a use for the GREY BULKYHEAD fitting that they provide.

Black line on top of canister = return fuel from the CP3

Factory tank vent = Air Dog return

Do not remove the grey tank vent on the canister, it is a 1 way check valve that allows air into the tank as you use (remove) fuel.

#15

Yes, I removed the pump from the canister, It was easy but as careful as I was, the pump mounts were not able to be saved.

However the factory pump makes a great parts washer pump!!!!!!!!