VE advance mechanism

#1

Registered User

Thread Starter

Join Date: Sep 2004

Location: Folsom CA

Posts: 963

Likes: 0

Received 0 Likes

on

0 Posts

VE advance mechanism

Well I got my hands on a nice pump for a pretty good price and I brought the thing home and tore it all apart.

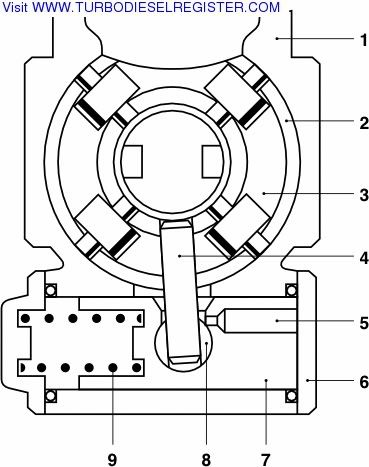

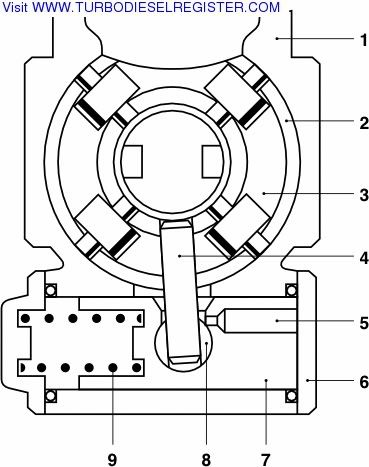

My questions are concerning the dynamic advance mechanism in the pump. I read an older thread about shaving 2mm off of the passenger side or retard side of the piston in the pump, and was wondering the outcome and what this translates to in degrees? or am i asking too much here .

.

My questions being, why 2mm? And why not shave off the advance side of the piston?

Just so I am clear here, the piston is at maximum advance when the engine is not running due to the spring forcing it to advance with no pressure on the opposite side of the piston to retard it. It appears that the piston receives pressure through the top opening, where pin #4 enters it, is this correct?

One last thing for the moment, does the KSB affect the movement of the piston in any way other than raising the case pressure which in turn forces the advance piston to move further advanced?

Cory

My questions are concerning the dynamic advance mechanism in the pump. I read an older thread about shaving 2mm off of the passenger side or retard side of the piston in the pump, and was wondering the outcome and what this translates to in degrees? or am i asking too much here

.

.My questions being, why 2mm? And why not shave off the advance side of the piston?

Just so I am clear here, the piston is at maximum advance when the engine is not running due to the spring forcing it to advance with no pressure on the opposite side of the piston to retard it. It appears that the piston receives pressure through the top opening, where pin #4 enters it, is this correct?

One last thing for the moment, does the KSB affect the movement of the piston in any way other than raising the case pressure which in turn forces the advance piston to move further advanced?

Cory

#2

Registered User

the piston is at maximum advance when the engine is not running due to the spring forcing it to advance

I measured up my core pump, and it looked as though you could allow the piston to travel out another 1/16th of an inch or so without doing any damage -- so I think that you could grind that side of the piston off -- you'd just have to make sure that the spring wouldn't end up fully compressed and stopping the piston travel.

The fellows who shave the other (retard) side then make adjustments in the pump to advance the timing on the cam ring so that the static timing is back up where it is stock, and they can get overall higher timing at full advance.

Hope that helped . . .

#3

Registered User

Thread Starter

Join Date: Sep 2004

Location: Folsom CA

Posts: 963

Likes: 0

Received 0 Likes

on

0 Posts

OK...I get it now, I just re-read some earlier threads and for some reason I confused myself.

The earlier threads said to shave the retard side and then set the base timing lower because you would have more dynamic advance available. Why not shave the advance side of the piston and modify or replace the spring if that became your limiting factor? Or why not modify both sides of the piston (there is a lot of unused range of motion in both directions of the piston)?

Last thing, I have read several times that during startup these pumps are at full advance, how can this be? Doesnt the spring force the timing piston to full retard when there is no internal pump pressure?

The earlier threads said to shave the retard side and then set the base timing lower because you would have more dynamic advance available. Why not shave the advance side of the piston and modify or replace the spring if that became your limiting factor? Or why not modify both sides of the piston (there is a lot of unused range of motion in both directions of the piston)?

Last thing, I have read several times that during startup these pumps are at full advance, how can this be? Doesnt the spring force the timing piston to full retard when there is no internal pump pressure?

#4

Registered User

At startup they're at full throttle, not full advance, AFAIK. Altering both ends of the piston is the way to go, in my mind. You would be able to run reasonable static timing, say 14-16* so the truck is driveable, but there's be plenty of travel in order to deliver lots of advance at higher rpms where we really need it. You could likely cut a coil or two from the spring to compensate for the shorter piston.

#5

Registered User

The pumps are at full retard during starting. However, they are at beyond full fueling. There is a spring that forces the control collar to the maximum fueling position when the governor is not spinning. So a very large amount of retarded fuel is injected at start-up (this is why we get that puff of smoke when we start the truck). I think somewhere timing and fueling must have gotten confused. For what it is worth, it is very hard to start an engine with a high degree of advance, because ignition tends to push the pistons back away from TDC if the engine is not spinning fast enough.

I would think that you could modify both sides of the piston and get some extra travel -- on my junk pump the piston will stick out almost an eighth of an inch on either side before the internal parts hit the case. I don't really know why shaving the retard side is the popular method, except that folks might be shying away from modifying the spring -- I don't think that enough pressure is built up to fully compress the spring under any circumstances . . .

I would think that you could modify both sides of the piston and get some extra travel -- on my junk pump the piston will stick out almost an eighth of an inch on either side before the internal parts hit the case. I don't really know why shaving the retard side is the popular method, except that folks might be shying away from modifying the spring -- I don't think that enough pressure is built up to fully compress the spring under any circumstances . . .

#6

Registered User

Thread Starter

Join Date: Sep 2004

Location: Folsom CA

Posts: 963

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the clarification about full fuel under startup but retarded timing.

You just brought up another question, you said that the pumps are "beyond" full fueling at startup. Are you saying that when the engine is running at WOT the control collar never completely closes the window port in the rotor? Even with a maxed out pump some fuel is still bypassing through that port? If so then there is more power available in these pumps that we are not taking advantage of.

I hear you about the advance mechanism, mine has almost 3/16" more travel in each direction, a lot to be desired. About the spring, looks like we need to find a softer or shorter alternative.

You just brought up another question, you said that the pumps are "beyond" full fueling at startup. Are you saying that when the engine is running at WOT the control collar never completely closes the window port in the rotor? Even with a maxed out pump some fuel is still bypassing through that port? If so then there is more power available in these pumps that we are not taking advantage of.

I hear you about the advance mechanism, mine has almost 3/16" more travel in each direction, a lot to be desired. About the spring, looks like we need to find a softer or shorter alternative.

#7

Registered User

Sorry Greg -- I had that reply window open for a while and hadn't seen your post . . .

As for the maxxed out pump, the problem is setting up the pump so that you can slide that collar all the way toward the rotor head, but still get it to come back so you do not have a run away . . . That is what grinding the AFC lever tries to do. The word on the street, though, seems to be the problem isn't getting the volume of fuel injected, but getting it injected in time to burn. You need to get the fuel into the cylinder, get it to ignite, and get it to mix with enough air to burn efficiently, all within a reasonably small timing window. The problem with the VE is that as you add more fuel, it draws out the length of injection, effectively retarding the timing . . .

As for the maxxed out pump, the problem is setting up the pump so that you can slide that collar all the way toward the rotor head, but still get it to come back so you do not have a run away . . . That is what grinding the AFC lever tries to do. The word on the street, though, seems to be the problem isn't getting the volume of fuel injected, but getting it injected in time to burn. You need to get the fuel into the cylinder, get it to ignite, and get it to mix with enough air to burn efficiently, all within a reasonably small timing window. The problem with the VE is that as you add more fuel, it draws out the length of injection, effectively retarding the timing . . .

Trending Topics

#9

Registered User

Thread Starter

Join Date: Sep 2004

Location: Folsom CA

Posts: 963

Likes: 0

Received 0 Likes

on

0 Posts

So advancing the timing would help to achieve getting the fuel injected in time to burn. I cant see how the injection event could be too long as that is set by the rotor itself?

#10

Adminstrator-ess

The longer the spill port is covered, the longer the injection event is. We have gone way beyond where the control collar is "supposed" to be with a turned up pump, a ground AFC lever and/or a modified AFC cone.

#11

Registered User

Thread Starter

Join Date: Sep 2004

Location: Folsom CA

Posts: 963

Likes: 0

Received 0 Likes

on

0 Posts

Isnt the length of the injection event controlled by the ports in the rotor and receiving ports in the rotor head and the volume is controlled by the control collar.

#12

Adminstrator-ess

The maximum length of time is limited by the rotor head in theory, but in practice the control collar doesn't keep the spill port covered that long.

#13

Registered User

Thread Starter

Join Date: Sep 2004

Location: Folsom CA

Posts: 963

Likes: 0

Received 0 Likes

on

0 Posts

The control collar will control the length of the injection event from idle up until WOT and at that point the injection event is then limited by the ports in the rotor and head.

A pump shop told me that the control collar fully closes the spill port under full throttle with a turned up pump.

A pump shop told me that the control collar fully closes the spill port under full throttle with a turned up pump.

#14

Registered User

Thread Starter

Join Date: Sep 2004

Location: Folsom CA

Posts: 963

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by wannadiesel

The maximum length of time is limited by the rotor head in theory, but in practice the control collar doesn't keep the spill port covered that long.

Good explanation on the fuel delivery/control collar. I hadn't thought about it in quite those terms, but it makes sense.

Good explanation on the fuel delivery/control collar. I hadn't thought about it in quite those terms, but it makes sense.