How to duplicate over the road reliability?

#1

Registered User

Thread Starter

After reading, drooling over and implementing some of the upgrades on this site (especially Jim Lanes!) it got me wondering...

What do over the road tractors have, that are designed for longevity, that our trucks don't?

What should be on the upgrade "A-list" for reliability, serviceability and longevity? I'm not talking about what NOT to do (hot injectors, lifts, etc) but specifically what "to-do". No flash, fun or glam - just pure functionality.

I drove a semi one summer in college but haven't been around them since. I know there are upgrades we can add to duplicate their experiences. I assume they don't have any systems that don't have a real and cost-returnable function right?

I assume it would include guages, filters, coolers, etc, etc...

How bout it?

What do over the road tractors have, that are designed for longevity, that our trucks don't?

What should be on the upgrade "A-list" for reliability, serviceability and longevity? I'm not talking about what NOT to do (hot injectors, lifts, etc) but specifically what "to-do". No flash, fun or glam - just pure functionality.

I drove a semi one summer in college but haven't been around them since. I know there are upgrades we can add to duplicate their experiences. I assume they don't have any systems that don't have a real and cost-returnable function right?

I assume it would include guages, filters, coolers, etc, etc...

How bout it?

#2

Adminstrator-ess

Mostly just real big parts.

We already have good stuff like an oil cooler, gear driven timing and accessories, and greaseable u-joints.

For an auto trans truck, lots of trans cooling capacity and an inline trans filter are a good idea. On a stick truck that works hard (regular towing in the 8,000 lb+ range) an electric oil pump feeding an oil cooler and filter would do a lot for the Getrag. At a minimum a hard working 5 speed needs an oil temp gauge so the driver knows when to shift to direct drive.

A good primary fuel filter (I like Davco) combined with a Cat 2 micron secondary filter would be a nice upgrade over our 15 micron single filter setup.

Things like bypass oil filters and coolant filters are not a bad idea, but they are not universal big-rig equipment. Many big trucks you see are either leased trucks, or fleet vehicles with a planned 5 year service life. In cases like that, low initial cost and minimal maintenance labor are the priority, not ultimate longevity.

We already have good stuff like an oil cooler, gear driven timing and accessories, and greaseable u-joints.

For an auto trans truck, lots of trans cooling capacity and an inline trans filter are a good idea. On a stick truck that works hard (regular towing in the 8,000 lb+ range) an electric oil pump feeding an oil cooler and filter would do a lot for the Getrag. At a minimum a hard working 5 speed needs an oil temp gauge so the driver knows when to shift to direct drive.

A good primary fuel filter (I like Davco) combined with a Cat 2 micron secondary filter would be a nice upgrade over our 15 micron single filter setup.

Things like bypass oil filters and coolant filters are not a bad idea, but they are not universal big-rig equipment. Many big trucks you see are either leased trucks, or fleet vehicles with a planned 5 year service life. In cases like that, low initial cost and minimal maintenance labor are the priority, not ultimate longevity.

#3

Registered User

Out on the road, stuff happens, even on big trucks, just not nearly so easily or often.

One place where the good old genuine big trucks are way better than more consumer oriented light-trucks is in the electrical system.

BIG wire, much bigger than necessary is the norm.

BIG heavy amperage toggle-switches, that can be picked up at any truck-stop and are universal fit, regardless of make/model, are employed for all switching functions, and they can be swapped out in minutes with common tools.

On a REAL truck, all the key does is turn on the power to the start-button and maybe the accessories.

The DIMMER-SWITCH is on the FLOOR, WHERE IT BELONGS, is universal, and simple to swap out.

All electrical systems begin and end at terminal-strips, with ring-terminals at each end of the wiring, making any trouble-shooting or repairs very straight-forward.

Gauge- and switch-panels are simply big flat panels that are fastened at the corners by thumb-screws = no laying in the floor trying to work on stuff that can't be seen, let alone reached.

The turn-signal mechanism is entirely independent of the column, being clamped to the outside, is universal, and NON-cancelling, meaning it stays where you put it, until you want it off, instead of snapping off right in the middle of a turn.

I could go on and on, but you get the idea.

I have driven newer big trucks that have went the way of the plastic pick-up trucks, with everything all "user-friendly" junk; I prefer the OLD, as they are better.

One place where the good old genuine big trucks are way better than more consumer oriented light-trucks is in the electrical system.

BIG wire, much bigger than necessary is the norm.

BIG heavy amperage toggle-switches, that can be picked up at any truck-stop and are universal fit, regardless of make/model, are employed for all switching functions, and they can be swapped out in minutes with common tools.

On a REAL truck, all the key does is turn on the power to the start-button and maybe the accessories.

The DIMMER-SWITCH is on the FLOOR, WHERE IT BELONGS, is universal, and simple to swap out.

All electrical systems begin and end at terminal-strips, with ring-terminals at each end of the wiring, making any trouble-shooting or repairs very straight-forward.

Gauge- and switch-panels are simply big flat panels that are fastened at the corners by thumb-screws = no laying in the floor trying to work on stuff that can't be seen, let alone reached.

The turn-signal mechanism is entirely independent of the column, being clamped to the outside, is universal, and NON-cancelling, meaning it stays where you put it, until you want it off, instead of snapping off right in the middle of a turn.

I could go on and on, but you get the idea.

I have driven newer big trucks that have went the way of the plastic pick-up trucks, with everything all "user-friendly" junk; I prefer the OLD, as they are better.

#4

All electrical systems begin and end at terminal-strips, with ring-terminals at each end of the wiring, making any trouble-shooting or repairs very straight-forward.

Gauge- and switch-panels are simply big flat panels that are fastened at the corners by thumb-screws = no laying in the floor trying to work on stuff that can't be seen, let alone reached.

Gauge- and switch-panels are simply big flat panels that are fastened at the corners by thumb-screws = no laying in the floor trying to work on stuff that can't be seen, let alone reached.

#5

Registered User

Join Date: Apr 2007

Location: Central Mi

Posts: 666

Likes: 0

Received 0 Likes

on

0 Posts

If they built cars & truck like that - they'd all be out of business in 10 yrs or less ...

nobody would need to buy a new vehicle except for show - "lookie me, I've got a new car" ...

Ya, I can really see Detroit , or Japan , or Germany building them like that...

Too say nothing about the costs....

If you want something like that check out a Bently or Rolls Royce...

Virtually trouble free and last nearly forever...

You can get a good deal on one 10 - 15 yrs old.

nobody would need to buy a new vehicle except for show - "lookie me, I've got a new car" ...

Ya, I can really see Detroit , or Japan , or Germany building them like that...

Too say nothing about the costs....

If you want something like that check out a Bently or Rolls Royce...

Virtually trouble free and last nearly forever...

You can get a good deal on one 10 - 15 yrs old.

#6

Registered User

Thread Starter

All I need is $$ & Time

#7

Administrator

I had a miserable time trying to debug a circuit after someone had hacked it up and it was almost impossible to decipher without the master schematic and of course the right revision.

I think it is done this way for the reason of when it needs to be destroyed if it is about to be captured. I you were to sever the bundle at each end of the harness you would not be able to reverse engineer it and reuse the equipment.

Jim

Trending Topics

#8

Registered User

Join Date: May 2007

Location: Tennessee Colony, Texas

Posts: 169

Likes: 0

Received 2 Likes

on

2 Posts

Just hope they do not wire them the way it is done for the military, all of the wires are the same color but the beginning and end of each circuit is identified with a collar and matching number. Example #200 imprinted on a metal tag at each end of the single wire.

I had a miserable time trying to debug a circuit after someone had hacked it up and it was almost impossible to decipher without the master schematic and of course the right revision.

I think it is done this way for the reason of when it needs to be destroyed if it is about to be captured. I you were to sever the bundle at each end of the harness you would not be able to reverse engineer it and reuse the equipment.

Jim

I had a miserable time trying to debug a circuit after someone had hacked it up and it was almost impossible to decipher without the master schematic and of course the right revision.

I think it is done this way for the reason of when it needs to be destroyed if it is about to be captured. I you were to sever the bundle at each end of the harness you would not be able to reverse engineer it and reuse the equipment.

Jim

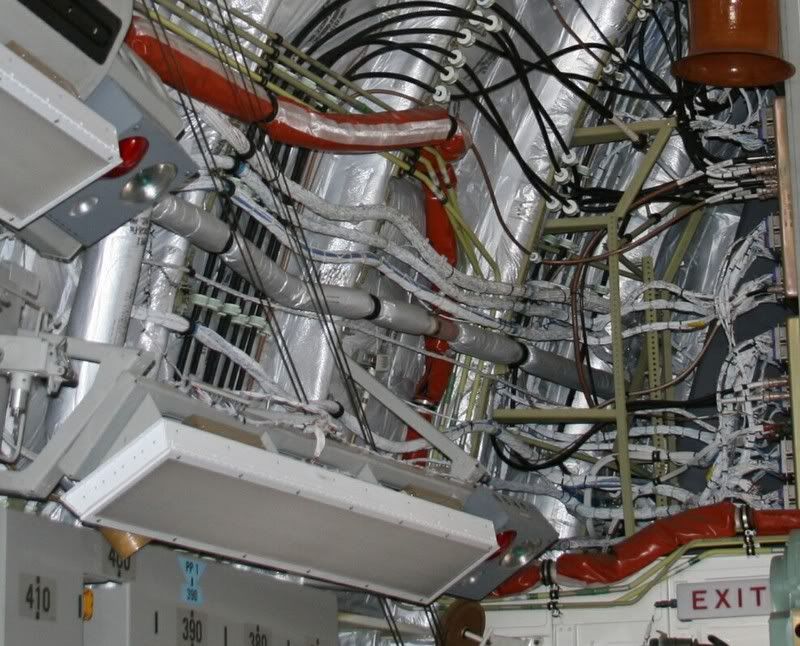

Oh and has anybody ever seen the wiring on a B-52??? Its SCARY!

Oh and has anybody ever seen the wiring on a B-52??? Its SCARY!

#9

Administrator

Looks like under my hood and dash.

While this not in a B-52 it is equally as big, I am impressed how all of the hundreds of wires go from the nose to the tail snaking their way through the many bulkheads while stopping many points along the way also all of the simple pulleys and cables to control the many flight surfaces on this huge airplane. Easy to see how a simple frag through the fuselage could put something out of commission.

A bit closer look.

Jim

#10

Registered User

Join Date: Jan 2007

Location: Oak Hills CA- Elizabeth City NC

Posts: 673

Likes: 0

Received 0 Likes

on

0 Posts

Just hope they do not wire them the way it is done for the military, all of the wires are the same color but the beginning and end of each circuit is identified with a collar and matching number. Example #200 imprinted on a metal tag at each end of the single wire.

I had a miserable time trying to debug a circuit after someone had hacked it up and it was almost impossible to decipher without the master schematic and of course the right revision.

I think it is done this way for the reason of when it needs to be destroyed if it is about to be captured. I you were to sever the bundle at each end of the harness you would not be able to reverse engineer it and reuse the equipment.

Jim

I had a miserable time trying to debug a circuit after someone had hacked it up and it was almost impossible to decipher without the master schematic and of course the right revision.

I think it is done this way for the reason of when it needs to be destroyed if it is about to be captured. I you were to sever the bundle at each end of the harness you would not be able to reverse engineer it and reuse the equipment.

Jim

#11

They use lighter wire in American vehicles to cut costs, plain and simple.

Like wannadiesel said, the big rigs (of old) have bigger parts, and are normally underpowered til an owner operator gets under the hood.

I agree with Bearkiller- I like the older stuff. I drove an early 80s KW for a farmer, and he also had a 98 Volvo. I actualy liked the KW better- had more of a "big rig" feel, even though the AC on the Volvo was colder.

Like wannadiesel said, the big rigs (of old) have bigger parts, and are normally underpowered til an owner operator gets under the hood.

I agree with Bearkiller- I like the older stuff. I drove an early 80s KW for a farmer, and he also had a 98 Volvo. I actualy liked the KW better- had more of a "big rig" feel, even though the AC on the Volvo was colder.

#12

heh, you ain't seen light wire until you look under the hood of one of these little ricers... I looked under a buddy's hood (Toyota something or another) and he was telling me how great Jap cars are cause they put the fuse box on the wheel well and stuff, and I am like "Dude, look at the wiring in this thing. Its like station wire... I used thicker wire when I installed commercial phone systems... this stuff... its barely even station wire... I wouldn't even wanna touch it... might snap off".

Thread

Thread Starter

Forum

Replies

Last Post

eds1997dodge

3rd Gen Engine and Drivetrain -> 2003-2007

9

11-28-2013 12:43 PM