Heads off. Got a few ?

#1

Heads off. Got a few ?

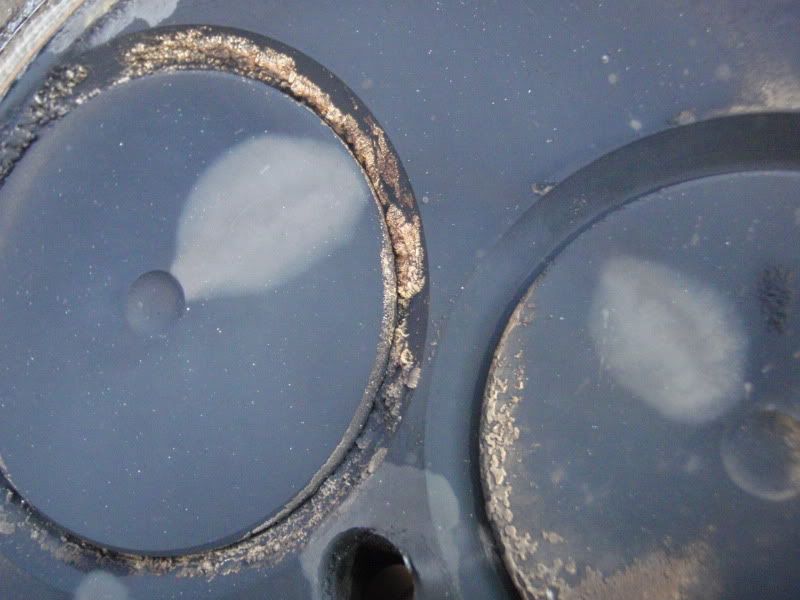

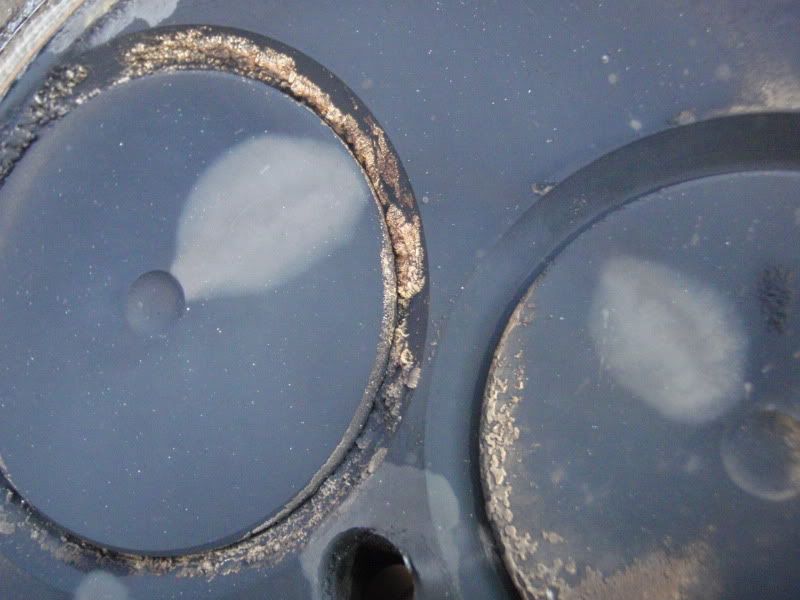

The heads off as you can see. In the pic's the intake valves are all carboned up. The backs of the valves have some oil on them but not much. Would you think this is from leaking valve seals or to much fuel no being burnt? This is causing the valves to hang open a bit I suspect.

I also suspect this is the cause of my smoke that builds when I sit a stop light or just idling.

Has anyone had something that looked like this before?

Thanks

I also suspect this is the cause of my smoke that builds when I sit a stop light or just idling.

Has anyone had something that looked like this before?

Thanks

#4

I use normal pump diesel with power service additive. I was running a liter of 2 stroke oil per tank but that was a year ago and haven't since. I drive the truck harder than a it was intended but not all the time.

The head is going to be reworked and a good port and valve job done on it. Maybe this will help.

Right now the way it runs it does not even haze under boost and only a puff before boost builds. My egt's never go past 1200deg F.

I was wondering if this was more a valve seal issue.

Thanks guys.

The head is going to be reworked and a good port and valve job done on it. Maybe this will help.

Right now the way it runs it does not even haze under boost and only a puff before boost builds. My egt's never go past 1200deg F.

I was wondering if this was more a valve seal issue.

Thanks guys.

#7

225,000km on it.

It was a daily driver for a year and a half. Some highway and some town. If there was no traffic I would be on it. Most of the time the only load on it is the 1980's fiberglass canopy. Once a year it goes for a 1500km one way hunting trip full of gear. This year it will be full and hauling a meat cooler trailer.

If this carbon build up is due to me not working it enough, what can I do to prevent this in the future? Different mod's?

Thanks

Yuri

It was a daily driver for a year and a half. Some highway and some town. If there was no traffic I would be on it. Most of the time the only load on it is the 1980's fiberglass canopy. Once a year it goes for a 1500km one way hunting trip full of gear. This year it will be full and hauling a meat cooler trailer.

If this carbon build up is due to me not working it enough, what can I do to prevent this in the future? Different mod's?

Thanks

Yuri

Trending Topics

#8

#9

So the heads at the machine shop. All checks out ok but they say the valves have ressesed into the head a bit and are .005 away from the cummins spec. After a valve grind they would be past the just over the spec. He suggested replacing the valves or machining the head to bring them back to with-in spec after the valve grind would be done.

Has anyone done this or had a simalar issue? Any help would be apprieciated.

thanks

Has anyone done this or had a simalar issue? Any help would be apprieciated.

thanks

#10

He wants to surface the head enough to get the valve protrusion back in spec? I'd only do that if the surface was warped enough to need that much taken off. The thinner the deck is the harder it is to get a good seal. Might as well do it right and replace the valves that need it.

If it's only exhaust valves, the seats are replaceable.

If it's only exhaust valves, the seats are replaceable.

#11

So the heads at the machine shop. All checks out ok but they say the valves have ressesed into the head a bit and are .005 away from the cummins spec. After a valve grind they would be past the just over the spec. He suggested replacing the valves or machining the head to bring them back to with-in spec after the valve grind would be done.

Has anyone done this or had a simalar issue? Any help would be apprieciated.

thanks

Has anyone done this or had a simalar issue? Any help would be apprieciated.

thanks

#12

So,

I elected to reuse the valves as they were still good. The seats are ok as well, both just need a grind and cut. I may loose a bit of compression but nothing that is going to concern me. It will be less than 1/4 of a point.

I had the porting guy look at it. He decided on what kind of valve job. The intake valves have a slight back cut to remove the lip just before the face of the valve. The exhaust he just did a stock grind. Im not sure what he did with the seats but they look good. Also the head was flat but had wear marks sunk into the surface from the flame ring. He suspects it was moving a bit. It seemed like it had etched the head. After all of this he ported it. He took a lot out of the exhaust bowl and smoothened out the intake swirl in the intake side. He also cleaned up the exhaust runners. Also he was able to remove 90% of the obstruction in the #1 intake runner.

During all of this I had the rocker towers machined to fit the ARP studs.

Here are some pic's

Just put it on and now to install the studs and rockers and push rods.

I elected to reuse the valves as they were still good. The seats are ok as well, both just need a grind and cut. I may loose a bit of compression but nothing that is going to concern me. It will be less than 1/4 of a point.

I had the porting guy look at it. He decided on what kind of valve job. The intake valves have a slight back cut to remove the lip just before the face of the valve. The exhaust he just did a stock grind. Im not sure what he did with the seats but they look good. Also the head was flat but had wear marks sunk into the surface from the flame ring. He suspects it was moving a bit. It seemed like it had etched the head. After all of this he ported it. He took a lot out of the exhaust bowl and smoothened out the intake swirl in the intake side. He also cleaned up the exhaust runners. Also he was able to remove 90% of the obstruction in the #1 intake runner.

During all of this I had the rocker towers machined to fit the ARP studs.

Here are some pic's

Just put it on and now to install the studs and rockers and push rods.

#14

Nice head. Looks like mine.

I really didnt screw with the runners tho.

I bet ur porter hated that bump before #1 cylinder. I know I sure did. I think the p-pump head im doing, I'll try milling part of the intake out and got that route.

that bump before #1 cylinder. I know I sure did. I think the p-pump head im doing, I'll try milling part of the intake out and got that route.

I really didnt screw with the runners tho.

I bet ur porter hated

that bump before #1 cylinder. I know I sure did. I think the p-pump head im doing, I'll try milling part of the intake out and got that route.

that bump before #1 cylinder. I know I sure did. I think the p-pump head im doing, I'll try milling part of the intake out and got that route.

#15

Rough cost

Port job $440, Rocker towers machined, $120, Head set from cummins $400, Valve job, decking, hot tank and magna flux $400, ARP studs $600. Sensor I broke $85. +oil and anti freeze.

Port job $440, Rocker towers machined, $120, Head set from cummins $400, Valve job, decking, hot tank and magna flux $400, ARP studs $600. Sensor I broke $85. +oil and anti freeze.