BC's Twin Install / AKA: "I'm Gonna Blow Up My Heap!" (updated as it occurs)

#31

Registered User

Join Date: Jan 2006

Location: Raleigh, NC

Posts: 1,237

Likes: 0

Received 0 Likes

on

0 Posts

#34

Registered User

Join Date: May 2004

Location: Golden, Colorado

Posts: 2,867

Likes: 0

Received 0 Likes

on

0 Posts

I would have to say its part of your crank shaft thrust bearing. It is not a very common failure on an automatic truck, but more prevalent on manual trucks. The original thrust bearings in these engines were of a 3 piece design that allows the thrust part of the bearing to come apart from the normal load part of the bearing. The new bearing from cummins is of a 1 piece design designed i'm assuming to prevent this failure in the future.

This is just my opinion and it may be completely wrong.

So just how did you get that pan out without taking the engine out?

This is just my opinion and it may be completely wrong.

So just how did you get that pan out without taking the engine out?

#36

Adminstrator-ess

I would have to say its part of your crank shaft thrust bearing. It is not a very common failure on an automatic truck, but more prevalent on manual trucks. The original thrust bearings in these engines were of a 3 piece design that allows the thrust part of the bearing to come apart from the normal load part of the bearing. The new bearing from cummins is of a 1 piece design designed i'm assuming to prevent this failure in the future.

This is just my opinion and it may be completely wrong.

So just how did you get that pan out without taking the engine out?

This is just my opinion and it may be completely wrong.

So just how did you get that pan out without taking the engine out?

Sounds like it's time to roll in some new main bearings.

At least the oil pan's off...

At least the oil pan's off...

#37

1st Generation Admin

Thread Starter

Crap . . . ........

So if I hadn't initiated this venture, . . . . . . . . . how long would I have had?

Here's a question unasked . . . . . Can the mains be swapped in frame?

Here's what I did with my mess. Another's truck may vary.

- Drain the engine coolant and transmission fluid.

- With a floor jack and 4x4 block, centered on that cross-member right under the radiator, raise the truck so the front axle is in droop by a couple or three inches.

- Remove the engine cooling fan and shroud.

- Disconnect the lower radiator hose from the block.

- Disconnect the charge-air tubing at the turbo's outlet, and the engine intake horn inlet.

- Remove the two nuts that connect the engine mounts to the cross-member (one each side).

- Remove the rear-most valve cover.

- Using the front engine lifting hoop, securely and safely lift the engine till the rear of the head is pretty-much against the firewall. Lifting till you just see the body begin to move is is about there.

- Remove the oil pan mounting bolts and have the pan rest on the cross-member.

- Remove the two bolts that hold the engine oil pick-up tube flange to the block (front passenger side).

- Remove the two bolts that hold the two oil pick-up tube braces to the block (drivers side)

- Letting the oil pick-up tube fall into the pan, slide the pan down and back to remove.

With that, I was VERY lucky in that as such, I had NO spare room.

You read that in the FSM. You're only suppose to read tha manual when all else fails.

So if I hadn't initiated this venture, . . . . . . . . . how long would I have had?

Here's a question unasked . . . . . Can the mains be swapped in frame?

So just how did you get that pan out without taking the engine out?

- Drain the engine coolant and transmission fluid.

- With a floor jack and 4x4 block, centered on that cross-member right under the radiator, raise the truck so the front axle is in droop by a couple or three inches.

- Remove the engine cooling fan and shroud.

- Disconnect the lower radiator hose from the block.

- Disconnect the charge-air tubing at the turbo's outlet, and the engine intake horn inlet.

- Remove the two nuts that connect the engine mounts to the cross-member (one each side).

- Remove the rear-most valve cover.

- Using the front engine lifting hoop, securely and safely lift the engine till the rear of the head is pretty-much against the firewall. Lifting till you just see the body begin to move is is about there.

- Remove the oil pan mounting bolts and have the pan rest on the cross-member.

- Remove the two bolts that hold the engine oil pick-up tube flange to the block (front passenger side).

- Remove the two bolts that hold the two oil pick-up tube braces to the block (drivers side)

- Letting the oil pick-up tube fall into the pan, slide the pan down and back to remove.

With that, I was VERY lucky in that as such, I had NO spare room.

#38

Registered User

Join Date: May 2004

Location: Golden, Colorado

Posts: 2,867

Likes: 0

Received 0 Likes

on

0 Posts

Crap . . . ........

Here's what I did with my mess. Another's truck may vary.

- Drain the engine coolant and transmission fluid.

- With a floor jack and 4x4 block, centered on that cross-member right under the radiator, raise the truck so the front axle is in droop by a couple or three inches.

- Remove the engine cooling fan and shroud.

- Disconnect the lower radiator hose from the block.

- Disconnect the charge-air tubing at the turbo's outlet, and the engine intake horn inlet.

- Remove the two nuts that connect the engine mounts to the cross-member (one each side).

- Remove the rear-most valve cover.

- Using the front engine lifting hoop, securely and safely lift the engine till the rear of the head is pretty-much against the firewall. Lifting till you just see the body begin to move is is about there.

- Remove the oil pan mounting bolts and have the pan rest on the cross-member.

- Remove the two bolts that hold the engine oil pick-up tube flange to the block (front passenger side).

- Remove the two bolts that hold the two oil pick-up tube braces to the block (drivers side)

- Letting the oil pick-up tube fall into the pan, slide the pan down and back to remove.

With that, I was VERY lucky in that as such, I had NO spare room.

Here's what I did with my mess. Another's truck may vary.

- Drain the engine coolant and transmission fluid.

- With a floor jack and 4x4 block, centered on that cross-member right under the radiator, raise the truck so the front axle is in droop by a couple or three inches.

- Remove the engine cooling fan and shroud.

- Disconnect the lower radiator hose from the block.

- Disconnect the charge-air tubing at the turbo's outlet, and the engine intake horn inlet.

- Remove the two nuts that connect the engine mounts to the cross-member (one each side).

- Remove the rear-most valve cover.

- Using the front engine lifting hoop, securely and safely lift the engine till the rear of the head is pretty-much against the firewall. Lifting till you just see the body begin to move is is about there.

- Remove the oil pan mounting bolts and have the pan rest on the cross-member.

- Remove the two bolts that hold the engine oil pick-up tube flange to the block (front passenger side).

- Remove the two bolts that hold the two oil pick-up tube braces to the block (drivers side)

- Letting the oil pick-up tube fall into the pan, slide the pan down and back to remove.

With that, I was VERY lucky in that as such, I had NO spare room.

As for how much time you might have had, probably would have kept running for a long time. I didn't know mine was gone until I put a new belt and tensioner on and with the new tensioner it kept walking the belt off of the ac compressor. Then I checked my crank end play with a pry bar and could move it in and out about 1/8".

Also while you have the pan off, I would recommend checking your piston cooling nozzles are still intact. I have heard that our year range are plastic and can possibly fail, the new ones are metal and less prone to failing. I wish I had known about this when I had my pan off.

Check my thread here:

https://www.dieseltruckresource.com/...+bearing+crank

#39

Adminstrator-ess

Monty rolled new bearings into his in-frame when his thrust bearing died.

If the crank wasn't slapping back and forth (unless you were going through belts left and right the it wasn't) it would probably run until a few more pieces fell out. You could just put the oil pan up and hope for the best - but I think that would bug you.

If the crank wasn't slapping back and forth (unless you were going through belts left and right the it wasn't) it would probably run until a few more pieces fell out. You could just put the oil pan up and hope for the best - but I think that would bug you.

#40

1st Generation Admin

Thread Starter

Perhaps one third of the way.

With the beginning of this project, I went into it not knowing of any issues.

Frankly, I'm leaning toward just putting it back together.

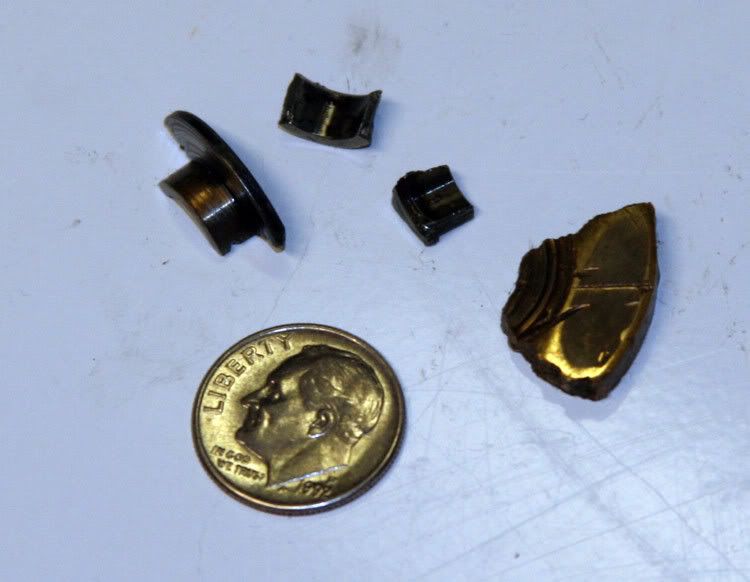

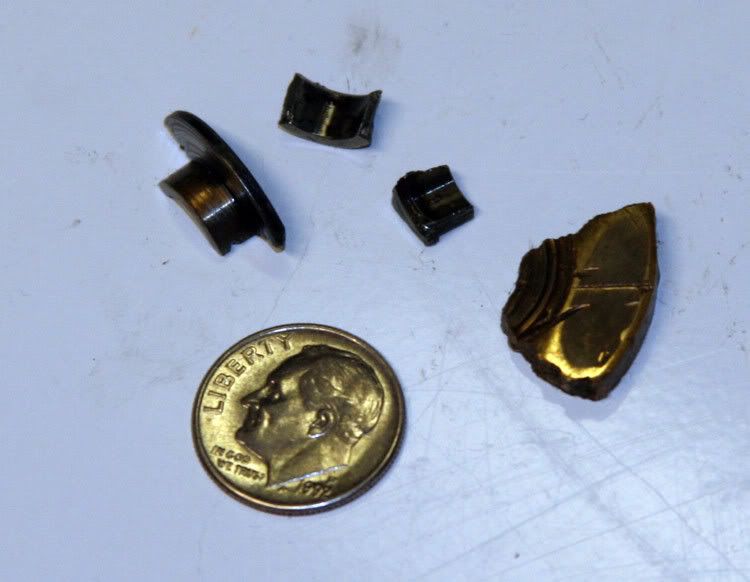

I've looked all through my Dodge/Cummins books and can't find anything (as far as inside the block) that could be where this bronze slug came from.

If I see that outer radius right, it appears to be wrong (too small) as compared to the main/thrust bearing. This shiny side appears to be that which rode in the bottom of the oil pan (for a while)

The other side is just as confusing. Trying to sort what might be normal wear marks versus those that came from subsequent grinding/failure.

The edges of the slug being dark and all indicate age. That boy's been in the pan a long time.

To be quite honest, these pieces worry me more . . . .

I've got the primary turbo's oil drain bung welded to the pan. I've still got to drill the actual hole and then paint it. Time allowing, I may just slip the pan back in tomorrow.

Thanks for the replies folks. It's not falling on deaf ears.

And yes, I need to clean under my nails.

Originally Posted by wannadiesel

Monty rolled new bearings into his in-frame when his thrust bearing died.

If the crank wasn't slapping back and forth (unless you were going through belts left and right the it wasn't) it would probably run until a few more pieces fell out. You could just put the oil pan up and hope for the best - but I think that would bug you.

If the crank wasn't slapping back and forth (unless you were going through belts left and right the it wasn't) it would probably run until a few more pieces fell out. You could just put the oil pan up and hope for the best - but I think that would bug you.

Frankly, I'm leaning toward just putting it back together.

I've looked all through my Dodge/Cummins books and can't find anything (as far as inside the block) that could be where this bronze slug came from.

If I see that outer radius right, it appears to be wrong (too small) as compared to the main/thrust bearing. This shiny side appears to be that which rode in the bottom of the oil pan (for a while)

The other side is just as confusing. Trying to sort what might be normal wear marks versus those that came from subsequent grinding/failure.

The edges of the slug being dark and all indicate age. That boy's been in the pan a long time.

To be quite honest, these pieces worry me more . . . .

I've got the primary turbo's oil drain bung welded to the pan. I've still got to drill the actual hole and then paint it. Time allowing, I may just slip the pan back in tomorrow.

Thanks for the replies folks. It's not falling on deaf ears.

And yes, I need to clean under my nails.

#43

Adminstrator-ess

David, I didn't realize the parts were so small.

When you fit them all together, it really does look like Rampage1967 said, pieces of a turbo bushing. Did your original turbo die early in the truck's life?

When you fit them all together, it really does look like Rampage1967 said, pieces of a turbo bushing. Did your original turbo die early in the truck's life?

#44

Registered User

Join Date: Apr 2007

Location: Central Mi

Posts: 666

Likes: 0

Received 0 Likes

on

0 Posts

OK Wanna ---

Instruct me ----

How can parts from a turbo get into the engine oil pan ??

I can't see a direct - or indirect, for that matter, - path except the turbo drain and that's pretty small....

Or maybe the parts are smaller than they look.

Instruct me ----

How can parts from a turbo get into the engine oil pan ??

I can't see a direct - or indirect, for that matter, - path except the turbo drain and that's pretty small....

Or maybe the parts are smaller than they look.

#45

At this point I've delivered all the hot parts so as to be coated (http://www.jet-hot.com/). Should be a week to ten days.

Messed around under the truck this evening for a couple of hours and pulled this out from under it.

More interestingly, found this in the bottom of the pan. Anybody lose something?

That item to the right appears to be made of brass or bronze. It's pushing an eight of an inch thick.

Messed around under the truck this evening for a couple of hours and pulled this out from under it.

More interestingly, found this in the bottom of the pan. Anybody lose something?

That item to the right appears to be made of brass or bronze. It's pushing an eight of an inch thick.

I'm just wondering how the Dime got in your oil pan,...