BC's Twin Install / AKA: "I'm Gonna Blow Up My Heap!" (updated as it occurs)

#136

Registered User

BC I notice you don't have a 1/8"npt bung welded in your cold pipe. This is very helpful when tuning your twins. Even just to see what pressure your primary is putting out.

#137

1st Generation Admin

Thread Starter

When it comes to tuning, I'm initially thinking things are pretty-much sorted out what with all the many installs there are of the same mess. Setting the waste-gate to open at 26psig readily pops out of everyone I've asked.

- What else could be tuned short of swapping exhaust housings etc.?

I think that with the grinding/blending/porting of things I've done there should be some advantage realized with a little tweaking albeit minor.

I've got a better torque wrench on the way to aid in ensuring the sealing of the head. It sports a 1% accuracy. I was talking with Brian Buchanan the other day and he suggested a torquing procedure that he and Jeff Garmon use.

We'll see.

I appreciate y'alls patients with me and this mess.

#138

Registered User

I've got a better torque wrench on the way to aid in ensuring the sealing of the head. It sports a 1% accuracy. I was talking with Brian Buchanan the other day and he suggested a torquing procedure that he and Jeff Garmon use.

We'll see.

I appreciate y'alls patients with me and this mess.

#139

Registered User

Dave, if you get things back up and running by thursday are you going to Dunn-Benson? If so i will be there also.In case you haven't heard i took runner up in the E.T. class sunday at our drags in J'ville. It was a hoot. Let me know. I hope every thing is going smoothly!! ...Augie

#140

1st Generation Admin

Thread Starter

Dave, if you get things back up and running by thursday are you going to Dunn-Benson? If so i will be there also.In case you haven't heard i took runner up in the E.T. class sunday at our drags in J'ville. It was a hoot. Let me know. I hope every thing is going smoothly!! ...Augie

I'll miss D/B this Thursday.

As of today I have all the parts along with a sporty new digital torque wrench. Naturaly, I'm on-call with work this week so if that doesn't interupt things, I'm planning on replacing the head gasket this weekend.

I am tempted to put in the new stud'n nut and pull it up and see what happens.

#142

1st Generation Admin

Thread Starter

OK, . . . . . .

The name of this thread is "BC's Twin Install / AKA: "I'm Gonna Blow Up My Heap!" (updated as it occurs)".

- Got the twins installed ~

- Blew it up ~

So the last update had my truck popping a nut (hehe) and squirting antifreeze along with combustion/compression gases around the stud between cylinders 3 and 4.

I rounded up the parts to replace the head-gasket as well as a replacement stud, nut and washer. And believe me, I've been whining like a two year old about it.

Wanna mentioned earlier about hoping replacing the nut would have it reseal. 50/50 chance.

So here's what I did . . . .

In the normal spiral pattern starting from the center,

- Individually removed each of the studs.

- Wiped them down.

- Reapplied ARP Assembly Lube to the stud, nut and washer.

- Reinstalled ensuring they are fully seated no more than hand tight.

- Pulled them up to 115ft/lbs.

- Let them rest for 30 minutes.

Then, in a line-torque pattern . . .

- Pull them up to 120ft/lbs.

- Let them rest for 30 minutes.

I continued with this 5lb increment/30 minute rest till they were at 135ft/lbs.

This was done with a digital torque wrench that has a neat feature in that it beeps when you get close to your target torque figure. It then holds a steady tone when you're at the target figure.

I found that simply pulling very slowly and steadily, the ARP lube allowed the nut to slide right around, the wrench would beep as I moved close, then steady. THEN it would beep more indicating the stud was actually stretching. Just keeping the steady pressure had the nut actually move quite a bit as things stretched and settled. (Hope this makes sense).

I don't think a regular "Clicker" type wrench would let you see how things react as such. It was most enlightening to me . .. . friggin Kewl!

Anyhoot, Pull'em up, adjust the valves, and fire it up. So far so good.

Let it come up to normal operating temp . . . so far so good.

Drive it into town and get some fuel . . . still good.

Today, start it and let it warm up, . . . still good. No green where it shouldn't be, the radiator reservoir isn't percolating and the engine oil isn't milky and steaming.

Take it to the drag-strip, . . .. and flog the immortal crap out of it. All appears well. >Imagine a really BIG sigh of relief<

>Imagine a really BIG sigh of relief<

The gist of it is, I'm down .4 seconds in the eighth as compared to the single. All aspects reflect a bit slower including the 60' times. I guess that shows the differences in spooling of a single vs twins. Dunno, it appears I've got to relearn launches so as to get the boost up while watching the Christmas tree

There might be a subtle decrease in initial pull, but then there's a new increase in pull the later half of the track.

Just to further complicate things, I also slipped in one of Denny-T's Stg2 fuel pins.

- My home-ground fuel pin combined with the twins would readily come up with 55lbs boost and creep up to almost 60lbs with the engine wound up. All the while, EGTs struggled to hit 1250*F.

- With the Denny-T Stg2 fuel pin, I think the ISSPRO 60lb gauge is pegging with the EGTs heading toward 1300*F.

It definitely puts more fuel to the squirter's.

Still need to do some fine tuning to get it all to its best but so far, I'm impressed.

- The bigger honk'in muffler keeps it stock quiet.

- The auxiliary transmission fluid cooler works like a champ. Between it and being able to conveniently valve off the heat exchanger, the fluid temp never went over 150*F during the coarse of four passes.

NICE!!

The name of this thread is "BC's Twin Install / AKA: "I'm Gonna Blow Up My Heap!" (updated as it occurs)".

- Got the twins installed ~

- Blew it up ~

So the last update had my truck popping a nut (hehe) and squirting antifreeze along with combustion/compression gases around the stud between cylinders 3 and 4.

I rounded up the parts to replace the head-gasket as well as a replacement stud, nut and washer. And believe me, I've been whining like a two year old about it.

Wanna mentioned earlier about hoping replacing the nut would have it reseal. 50/50 chance.

So here's what I did . . . .

In the normal spiral pattern starting from the center,

- Individually removed each of the studs.

- Wiped them down.

- Reapplied ARP Assembly Lube to the stud, nut and washer.

- Reinstalled ensuring they are fully seated no more than hand tight.

- Pulled them up to 115ft/lbs.

- Let them rest for 30 minutes.

Then, in a line-torque pattern . . .

- Pull them up to 120ft/lbs.

- Let them rest for 30 minutes.

I continued with this 5lb increment/30 minute rest till they were at 135ft/lbs.

This was done with a digital torque wrench that has a neat feature in that it beeps when you get close to your target torque figure. It then holds a steady tone when you're at the target figure.

I found that simply pulling very slowly and steadily, the ARP lube allowed the nut to slide right around, the wrench would beep as I moved close, then steady. THEN it would beep more indicating the stud was actually stretching. Just keeping the steady pressure had the nut actually move quite a bit as things stretched and settled. (Hope this makes sense).

I don't think a regular "Clicker" type wrench would let you see how things react as such. It was most enlightening to me . .. . friggin Kewl!

Anyhoot, Pull'em up, adjust the valves, and fire it up. So far so good.

Let it come up to normal operating temp . . . so far so good.

Drive it into town and get some fuel . . . still good.

Today, start it and let it warm up, . . . still good. No green where it shouldn't be, the radiator reservoir isn't percolating and the engine oil isn't milky and steaming.

Take it to the drag-strip, . . .. and flog the immortal crap out of it. All appears well.

>Imagine a really BIG sigh of relief<

>Imagine a really BIG sigh of relief<The gist of it is, I'm down .4 seconds in the eighth as compared to the single. All aspects reflect a bit slower including the 60' times. I guess that shows the differences in spooling of a single vs twins. Dunno, it appears I've got to relearn launches so as to get the boost up while watching the Christmas tree

There might be a subtle decrease in initial pull, but then there's a new increase in pull the later half of the track.

Just to further complicate things, I also slipped in one of Denny-T's Stg2 fuel pins.

- My home-ground fuel pin combined with the twins would readily come up with 55lbs boost and creep up to almost 60lbs with the engine wound up. All the while, EGTs struggled to hit 1250*F.

- With the Denny-T Stg2 fuel pin, I think the ISSPRO 60lb gauge is pegging with the EGTs heading toward 1300*F.

It definitely puts more fuel to the squirter's.

Still need to do some fine tuning to get it all to its best but so far, I'm impressed.

- The bigger honk'in muffler keeps it stock quiet.

- The auxiliary transmission fluid cooler works like a champ. Between it and being able to conveniently valve off the heat exchanger, the fluid temp never went over 150*F during the coarse of four passes.

NICE!!

#150

1st Generation Admin

Thread Starter

I apologize, I've been meaning to post a follow-up but have run into and corrected a few minor bugs since. I'd wanted to have some useful results to post with it.

I apologize, I've been meaning to post a follow-up but have run into and corrected a few minor bugs since. I'd wanted to have some useful results to post with it.Anyhoot, yes, I'm finished with the twin install . . . .

All in all, I'd say the "Kit" from PDR is a well thought out collage of parts. It's complete with the exception of the primary support brace.

In MY install, I did a bunch of extra things (relocate heat exchanger, add remote cooler, etc). Those aside, the turbo thing was relatively quick in it's install. With my moderate fueling (regular DDP4s, Denny-T pin, typical maxed IP, etc), I'm seeing 60+ psig at the head's intake log. That's with a fairly well ported head too. EGT's are less than 1350*F max.

Keeping in mind that my side-by-side comparison of the single vs the twins is skewed a bit with my also swapping my heavily "Home-Cut" fuel-pin with a Denny-T stage-2 pin . . .. .

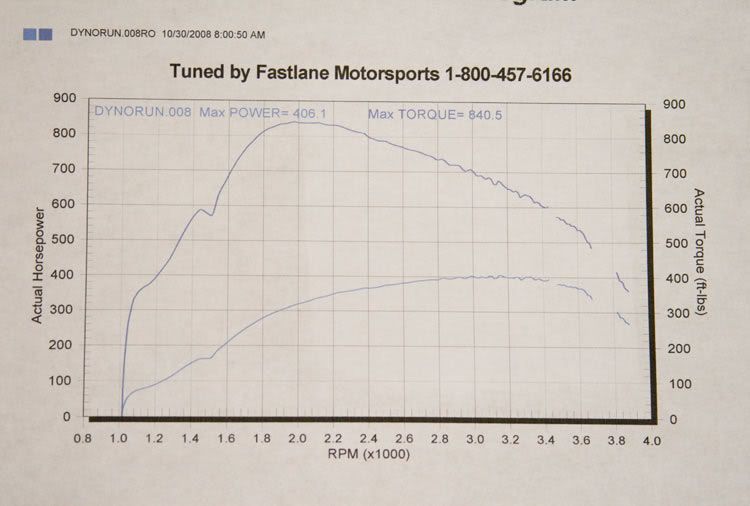

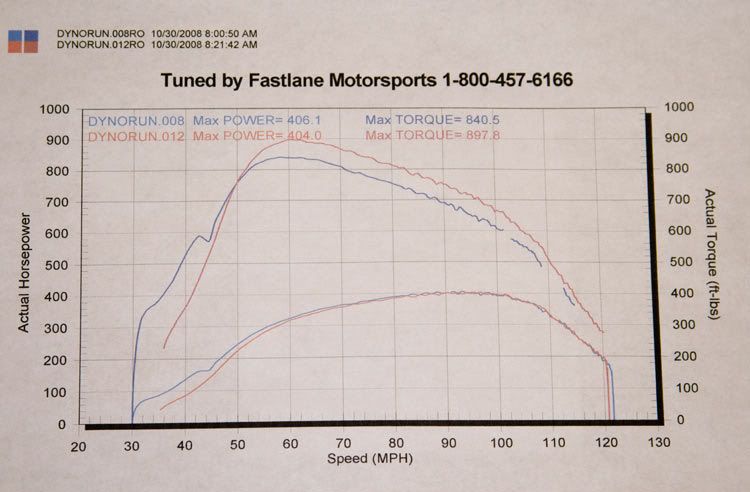

On number 2 only, I've gone from 395HP / 725ft/lbs to 406HP / 840ft/lbs (uncorrected).

Adding W/M does little as I've not addressed the impact the additional boost has on the W/M system's working pressure (spraying less). In fact, if all was the same, I lost two horsepower but picked up an additional 57ft/lbs of torque (red graph with W/M, blue without) . . .

Based on the above graph, if I want to go any faster in speed (MPH), I'm gonna have to spin the engine higher than the 3200 rpm governor spring will allow.

Since completing the twins install, and before the latest dyno run, I've parked the 2nd Gen piston lift-pump for a Walbro 392. As such, I've a rock solid 19psig at the IP inlet.

I made a few passes at the Fayetteville Motorsports Park today and appear to be fairly consistent at 13.9+ in the quarter. My best today was 13.90 @ 97.78.

There's a new concern though as it seems the trans might be slipping slightly if not being a bit slow in shifting from 2nd to 3rd. Not sure what it's doing. It's all happening too fast and somebody's got to drive! To my amazement, it appears I broke traction at least once in a 1st to 2nd gear shift. In four wheel drive!!!

With that, I'm done hopping-up my heap. I've known all along that a chain is only as strong as it's weakest link, and with the way I've been flogging my mess, I've been real lucky (you have to have my last name to fully understand). I'll probably get some EDM's to flow a little more fuel, maybe not as big as the 6x16's, but that will be it.

As far as addressing any possible slip in the trans, it only does it at the track, and I currently think it can be addressed by dinking with the valve-body some. I'm not gonna burn a clutchpac in the meantime.

They say one can comfortably assume anywhere from 20% to 30% being lost in the drive-train, so a solid 400RWHP should be around 500HP at the flywheel. Seeing as it was 160HP from the factory, I'm happy with it all.

Mission accomplished, I'm tickled.

Thanks for riding with me in this thread. I hope it's been worth your time.

Next, that rat's nest of a wiring . . . . . . . . . thing.