1985 CrewCab Road Tractor build

#61

Registered User

Thread Starter

I think the reason for the staggered shock mounts is to help reduce axle wrap. Those u-bolts were from Tough Country via Summit racing. I have the part number some where around here. I chose them because I can bolt a track bar under the axle saddles vs welding to the saddles.

#62

Registered User

Thread Starter

I will see if I can locate any of the pictures of my D80 swap on my white crew cab years ago.

I used the flat style of u bolt saddle that usually come on the 2nd gen C+C or dually trucks with the D80. These saddles are different than the standard pick up style saddle for the Dana 80 and also seem more robust. Then I cut a shock mount off a 1st gen saddle and welded the 1st gen D70 shock mount and support onto the D80 saddle. I then had to weld in and re drill the holes for the 2 1/2 inch wide spring on the 1st gen rather than the 3 inch wide springs that the 2nd gen trucks with the Dana 80 came with.

After I just cut off the 2nd gen shock mounts off the axle.

Things are looking good really good buddy!

EDIT: I see in your pictures you are using the D80 dually style u bolt saddles similar to ones I welded the 1st gen shock support on to.

I used the flat style of u bolt saddle that usually come on the 2nd gen C+C or dually trucks with the D80. These saddles are different than the standard pick up style saddle for the Dana 80 and also seem more robust. Then I cut a shock mount off a 1st gen saddle and welded the 1st gen D70 shock mount and support onto the D80 saddle. I then had to weld in and re drill the holes for the 2 1/2 inch wide spring on the 1st gen rather than the 3 inch wide springs that the 2nd gen trucks with the Dana 80 came with.

After I just cut off the 2nd gen shock mounts off the axle.

Things are looking good really good buddy!

EDIT: I see in your pictures you are using the D80 dually style u bolt saddles similar to ones I welded the 1st gen shock support on to.

I also use a piece of 3" square tube with 0.25" wall for my upper u-bolt plate. They fit nicely over the 2.5" D250 spring and worked with the new u-bolts for a 2nd gen.

#63

Registered User

I am liking the 3 inch square tubing trick for the top of the spring pack.

Welding up the 3 inch wide spring holes in the u bolt saddle, just to drill them out 2 1/2 wide was a pain.

I am trying out that trick next time I roll a 2nd gen Cummins axle under a 1st gen.

Welding up the 3 inch wide spring holes in the u bolt saddle, just to drill them out 2 1/2 wide was a pain.

I am trying out that trick next time I roll a 2nd gen Cummins axle under a 1st gen.

The following users liked this post:

nothingbutdarts (01-18-2024)

#64

Registered User

Thread Starter

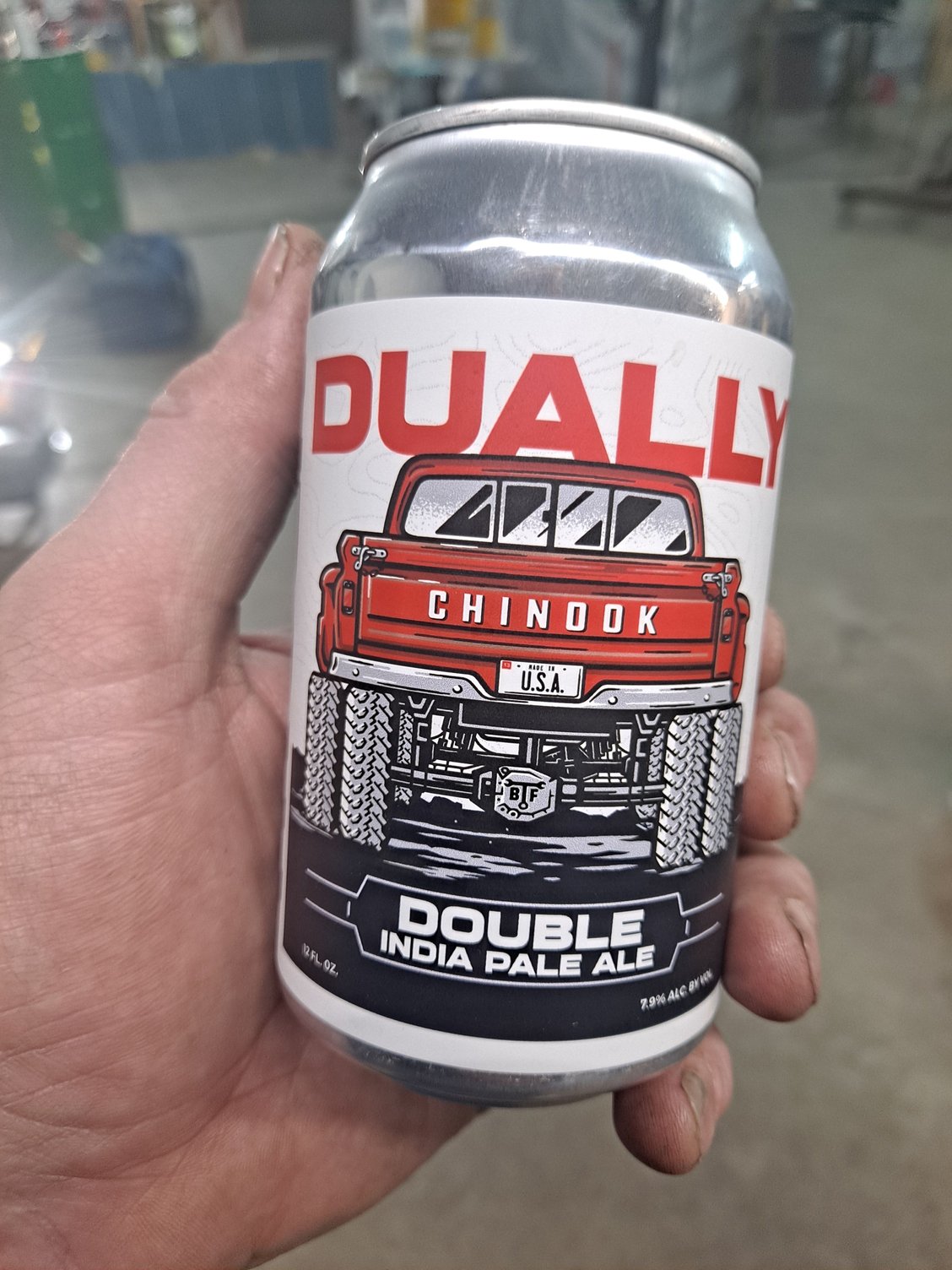

I spent a day prepping parts for a second round of Epoxy primer and a few top coats of acrylic urethane gloss black. I hate to paint and a few DIPA's made it a little more bearable. Next is nut and bolt work. Oliver you can check out all this fancy paint in a few months!

#66

Registered User

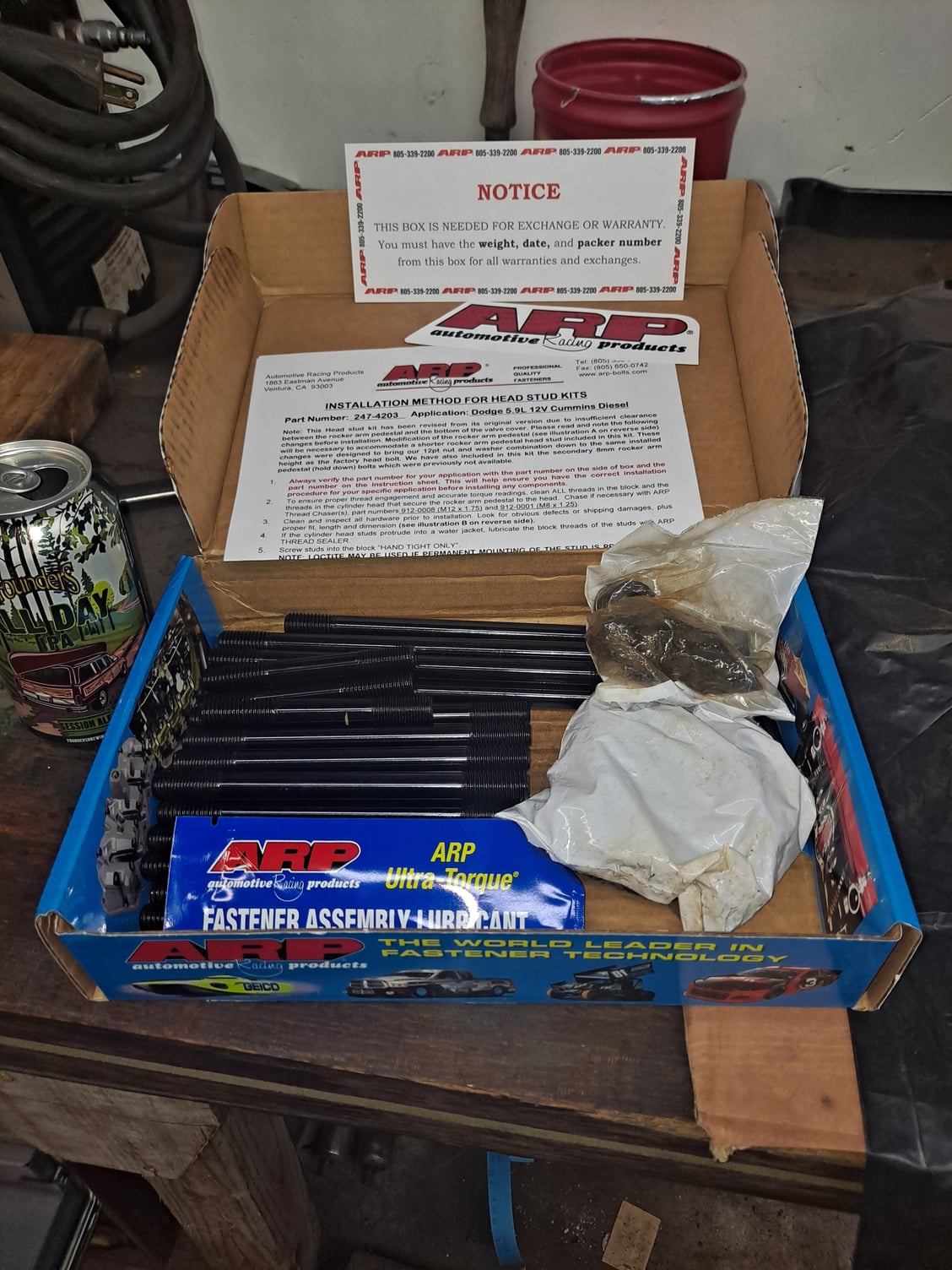

I set the head back on and finally decided to go with ARP head studs. And I figured since it's going in an '85 Dodge, that I'll go with the period correct Cummins Beige. I'm not a huge fan of spray paint in a can, and I'm interested to see how this holds up after a couple heat cycles.

And a good IPA can make almost anything bearable. Dually is another new one for me.

#67

Registered User

Thread Starter

KRB, the rocker stands had to be cut about 0.25" , you can see that in the pic without the rocker covers.

Big Truck Brewing makes the Dually. Good stuff, I am still waiting on a 1st gen to show up on one of their labels.

Big Truck Brewing makes the Dually. Good stuff, I am still waiting on a 1st gen to show up on one of their labels.

#68

Registered User

A month ago when you where posting pictures of a stripped frame on a trailer, headed out to be cleaned up... I was worried you would run out of days in the week to get it done before Carlisle.

I am now thinking you are in a pretty good spot to pull this off!

You are making great head way for the quality of work being done. I know this takes a lot of time.

I want to sit on the tailgate and cruise around Carlisle next July in this ride. Maybe it can be the "taxi" to drive up to the race course for the street shootout.

I am now thinking you are in a pretty good spot to pull this off!

You are making great head way for the quality of work being done. I know this takes a lot of time.

I want to sit on the tailgate and cruise around Carlisle next July in this ride. Maybe it can be the "taxi" to drive up to the race course for the street shootout.

#69

Registered User

Thread Starter

It has been a busy couple of weeks with bad wearher and other nonsense going on. I have been spending every spare hour I have trying to get this together. Next is a transmission crossmember and RamCharger fuel tank, followed by cab repair. I am hopefully almost out of the dirty work and it will soon be a matter of bolting stuff together.

The following 5 users liked this post by BHD:

brentm (02-01-2024),

edwinsmith (02-02-2024),

NJTman (02-01-2024),

nothingbutdarts (02-01-2024),

oliver foster (02-01-2024)

The following 2 users liked this post by KRB:

nothingbutdarts (02-01-2024),

oliver foster (02-01-2024)

#72

Registered User

Join Date: Dec 2010

Location: Land of the Toxic Avenger

Posts: 6,781

Received 1,645 Likes

on

1,118 Posts

It has been a busy couple of weeks with bad wearher and other nonsense going on. I have been spending every spare hour I have trying to get this together. Next is a transmission crossmember and RamCharger fuel tank, followed by cab repair. I am hopefully almost out of the dirty work and it will soon be a matter of bolting stuff together.

Nice resoration / build going on. Carlisle here you come.

The following users liked this post:

NJTman (02-04-2024)

#74

Registered User

Thread Starter

So, with a 3° set back for the engine I found that the starter will not clear the top frame flange. I read and reread about every post and article and YouTube video regarding putting a G56 in a 1st gen. Every one states the starter clears with no problem. Then I realized that no one was swapping a G56 into a 2wd CrewCab chassis! So I took measurements of the 91.5 that I used for the 4wd dimensions. Sure enough the 2wd top flange is wider. A little trimming with the 4 inch slicer wheel fixed the issue.

#75

Registered User

Ah the pain of cutting into fresh paint. Props, for the clean straight cut.

I was wondering about frame clearance with my 2nd gen adapter plate / starter for the 47RH on my 2wd D-250 frame under my pop top Ramcharger. I got lots of mixed answers as well from the internet.

It worked out, and fit for me in the end after I got my transmission crossmember where I wanted it {lowered a bit}.

I was wondering about frame clearance with my 2nd gen adapter plate / starter for the 47RH on my 2wd D-250 frame under my pop top Ramcharger. I got lots of mixed answers as well from the internet.

It worked out, and fit for me in the end after I got my transmission crossmember where I wanted it {lowered a bit}.