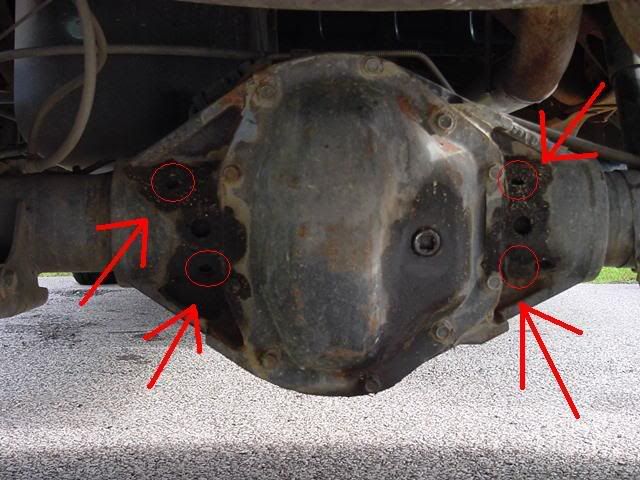

What is the possibility of the Dana 80 leaking from these spots? PIC!

#1

Now this is an older picture, the whole axle has been de-greased and spit shined... there is NO dirt on it and its NOT seeping from the seal...

Note the red circles and arrows...

I know those are used to secure the tubes into the carrier...

I swear that mine is pinhole leaking from those spots...

No drips, runs or puddles, but after degreasing the crap out of it yet again, I put a q-tip in the hole and there was what looked like a small offering of diff. fluid on it and it smelled like said fluid.

On my old '95, I believe it did this on the Dana 60 that was on it...

Has ANYONE heard about these leaking?

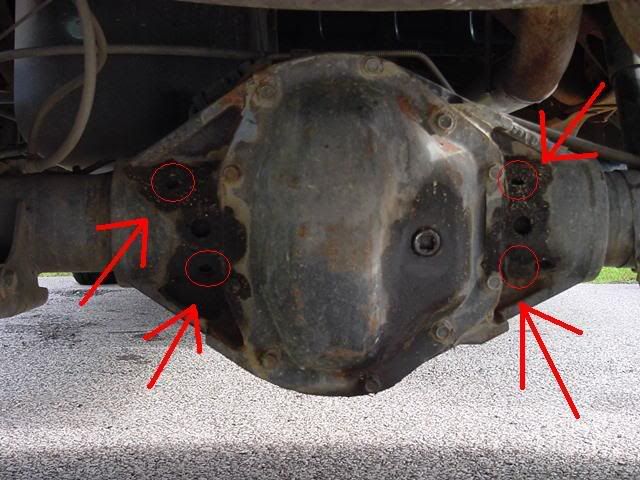

Note the red circles and arrows...

I know those are used to secure the tubes into the carrier...

I swear that mine is pinhole leaking from those spots...

No drips, runs or puddles, but after degreasing the crap out of it yet again, I put a q-tip in the hole and there was what looked like a small offering of diff. fluid on it and it smelled like said fluid.

On my old '95, I believe it did this on the Dana 60 that was on it...

Has ANYONE heard about these leaking?

#3

#7

Trending Topics

#8

I would personally just take a mig, and fill the holes in at the bottom. I would try to keep from getting it real hot. It may not hurt anything, but if it were me, id do a little, and let it cool off, and repeat. Just enough to completely fill the bottom of the hole. Or maybe even fill it in with JB weld(might be the easiest).

Eric

Eric

#9

I would personally just take a mig, and fill the holes in at the bottom. I would try to keep from getting it real hot. It may not hurt anything, but if it were me, id do a little, and let it cool off, and repeat. Just enough to completely fill the bottom of the hole. Or maybe even fill it in with JB weld(might be the easiest).

Eric

Eric

#10

I have no idea what it would leak, and no, I havent ever heard of one doing it, but im just saying that is what I would do if it was man, and was, in fact leaking from those holes.

Eric

Eric

#11

my Dana 80 looks like that..... i dono i might just JB weld over that.... if you weld cast iron (like a rear end housing) you HAVE to get it red hot for any type of welder to penetrate into the metal. also use a high nickle or stainless rod to stick weld it.... so i'm just gonna jb weld it sand it smooth and paint it black.

#12

That's just the plug welds from the factory. Either it wasn't a perfect weld from assembly or the weld may have cracked a bit? Either way, I'd weld 'er right up again. You could talk to an axle builder like dynatrac, they press their own tubes into their own cast center sections and they can tell you if there's any tricks to welding it up.

www.dynatrac.com

www.dynatrac.com

#13

I'd weld it up too. Welding in that area (unless you welded a lot) shouldn't cause any warpage.

I've seem some similar things with toyota axles on crawlers. From all the abuse they'd take, they would end up cracking. To fix it, guys would drill the ends of the cracks (to stop them), grind a "valley" in the crack and then weld over it.

I've seem some similar things with toyota axles on crawlers. From all the abuse they'd take, they would end up cracking. To fix it, guys would drill the ends of the cracks (to stop them), grind a "valley" in the crack and then weld over it.

#14

If that's cast iron, you'd be much better off trying jb weld first. I put jb weld in a much more hostile environment one time and had it seal perfectly-it held hot coolant for 2 years until that motor popped a headgasket. (not a diesel, it was a /6)

#15

Leaks

My dana 80 is doing the same thing only not quite that bad yet although I do keep my underside clean. I have a pressure washer. I would be interisted in knowing. I may investigate this now.